When evaluating DTF production, understanding DTF gangsheet builder pricing is essential for indie brands weighing cost against value. This article breaks down the factors behind that pricing, from upfront software or hardware costs to per-sheet DTF printing costs. We’ll also compare what you can expect to pay for a gangsheet printer price and how that upfront expense translates to per-item savings. By mapping costs to your run size, design complexity, and SKU count, you’ll see how the pricing model affects margins and price competitiveness. This prompts the question: is DTF worth it for indie brands, depending on volume, lead times, and waste reduction potential through smarter layouts.

Beyond the headline price, the discussion shifts to how a layout optimization tool affects production efficiency. LSI principles link terms such as multi-design transfer packing, sheet tiling accuracy, color management integration, and DTF printing costs to the same decision. Think of it as a workflow upgrade that reduces waste, saves ink and film, and shortens prepress time, rather than a single purchase. The real value is measured in how many designs you can fit on a sheet, how reliably colors stay consistent, and how the licensing scales with your team. When evaluating options, consider both the upfront sticker price and the longer-term savings on materials, labor, and turnaround.

1) Understanding the DTF gangsheet builder: what it does and how it impacts costs

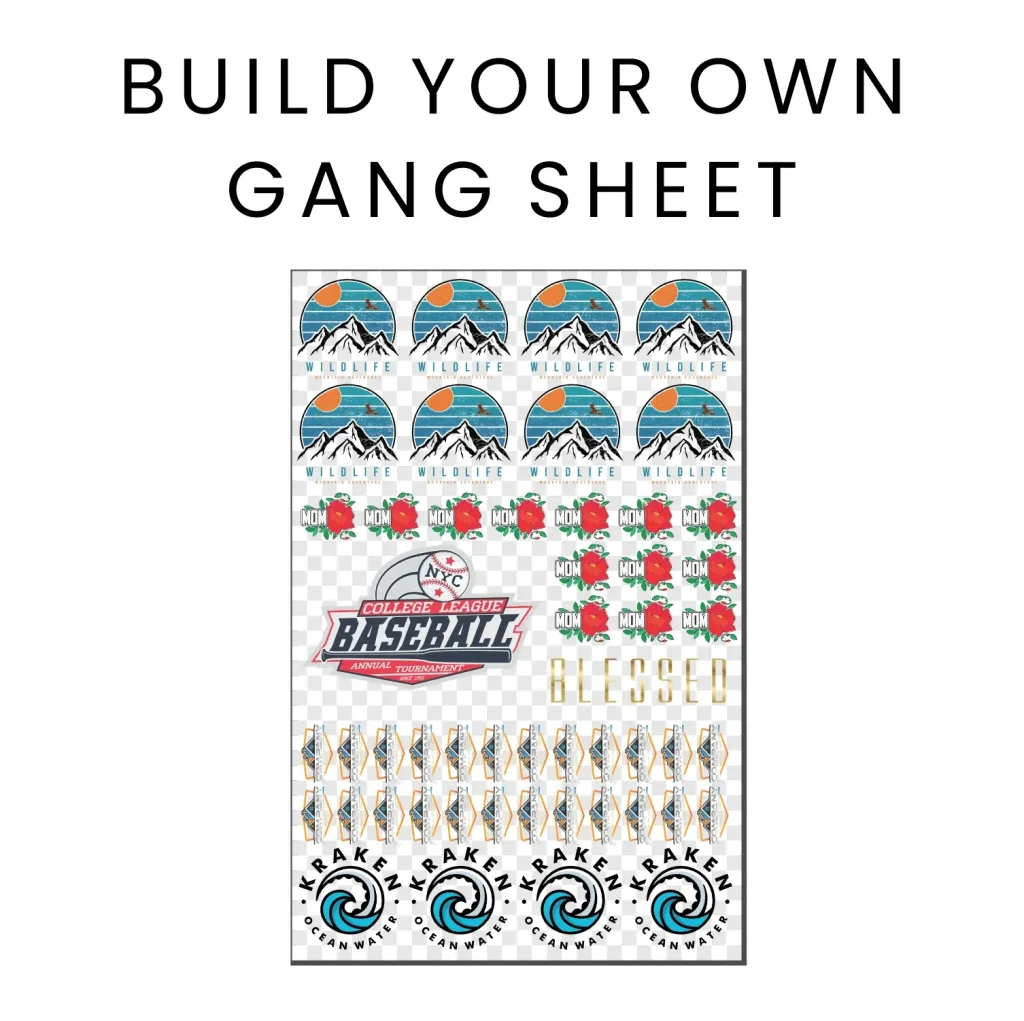

A DTF gangsheet builder is the workflow tool that arranges multiple designs on a single transfer sheet, maximizing how many prints you can pull from one film. For indie brands, this means you can pack more artwork per sheet, reduce wasted film, and streamline prepress time. By understanding how the tool lays out designs, you also gain insight into the potential reductions in DTF printing costs and how that translates to faster turnarounds and better margins.

The cost impact isn’t just the price of the software or hardware; it’s about how the tool integrates with your existing printer, RIP, and heat-press setup. Features like automatic tiling, bleed control, and color management can dramatically cut setup time and minimize reprints, which directly influences the total cost of ownership (TCO) over 12, 24, or 36 months.

2) DTF gangsheet pricing models: upfront fees, subscriptions, per-sheet charges, and TCO

Pricing for a DTF gangsheet builder typically falls into several models. You might encounter upfront software or hardware costs, subscription plans, or bundles that include a gangsheet printer or related workflow platform. The choice affects cash flow and long-term affordability, and it often hinges on features, the number of users, and whether cloud-based services are involved.

Another common approach is per-sheet or per-transfer pricing, which can be attractive for smaller runs but may scale poorly as your volume grows. Tiered plans and add-ons—for auto-spacing, advanced color management, or deeper integration with your RIP—can further influence the total cost of ownership and should be weighed against anticipated production demand and team size.

3) How gangsheet efficiency reshapes DTF printing costs for indie brands

When you optimize layouts to fit more designs on a single sheet, the effective cost per transfer declines. This is where the interplay between DTF printing costs and gangsheet pricing becomes tangible: more efficient sheets mean less film and ink per design, reduced waste, and faster setup. If your gangsheet printer price is offset by significant savings in consumables and labor, the math can become noticeably favorable.

However, the opposite can also be true. If the gangsheet tool is expensive relative to your output volume, or if you’re printing only a few designs with high color counts, the payback period can stretch. The decision hinges on run size, SKU count, and how consistently you can keep designs packed onto sheets with minimal waste.

4) Is it worth it for indie brands? ROI drivers, risks, and practical guidance

is DTF worth it for indie brands is a central question many founders ask. ROI tends to improve when you print sizable monthly volumes across multiple designs and can dramatically cut film usage, waste, and labor time. Full-color artwork and photorealistic designs particularly benefit from gangsheet efficiency, as more designs fit onto each sheet without sacrificing print quality.

That said, there are risks to consider: upfront capital, a learning curve, and potential dependency on a single vendor’s ecosystem. For brands with steady growth and diverse SKUs, the long-run savings from reduced material costs and faster production cycles often justify the investment. For very small runs or simple designs, a lighter approach or a pay-as-you-go model might be more prudent.

5) Selecting the right DTF gangsheet tool: compatibility, licensing, and support

Choosing a tool means confirming compatibility with your printer and RIP, ensuring color management aligns with your brand standards, and verifying that outputs will integrate seamlessly with your heat-press workflow. The ideal DTF gangsheet builder should streamline prepress, not complicate it, with clear documentation, intuitive tiling, and reliable output profiles.

Licensing, scalability, and support are equally important. Consider multi-user licenses for design teams, cloud-based collaboration if you work with remote collaborators, and the availability of onboarding resources or a community forum. A pilot or trial period can reveal real-world savings and help quantify metrics like sheets per hour, waste rate, and per-item reduction in costs.

6) Practical tips to optimize gangsheet layouts, color management, and waste reduction

Effective planning is foundational. Build a library of reusable design templates and modular layouts so you can quickly assemble gang sheets with minimal last-minute adjustments. Consistent color profiles across designs prevent costly reprints caused by color mismatches, improving reliability in production.

Beyond planning, strategic testing and material efficiency drive savings. Run small test batches to validate layout integrity and heat-press timing before committing to larger runs. Use high-quality film and transfer sheets optimized for gangworking, and monitor ROI by tracking sheets per hour and waste reductions. Regularly review performance data to adjust run sizes or layouts to sustain cost efficiency over time.

Frequently Asked Questions

What components are typically included in DTF gangsheet pricing?

DTF gangsheet pricing typically includes upfront software or hardware costs (or a subscription), and ongoing per-sheet fees plus maintenance. When evaluating, also account for DTF printing costs such as consumables and labor to understand total cost of ownership.

How does DTF gangsheet pricing affect DTF printing costs for indie brands?

Packing multiple designs on a single gangsheet lowers per-transfer costs and can reduce DTF printing costs overall. However, upfront tool costs and ongoing fees can affect break-even timing, especially at small volumes.

Is the gangsheet printer price a major factor in DTF gangsheet pricing?

Yes—the gangsheet printer price often ties into overall DTF gangsheet pricing, especially in bundles. For indie brands, calculate ROI before committing to a printer-and-builder package to determine if it’s a good fit for your business.

What should I consider when comparing DTF gangsheet pricing options for indie brands?

Look at compatibility with your RIP/printer, ease of use, licensing terms, and available support. Also estimate the total cost of ownership and potential ROI to judge if the option makes sense for your goals and whether is DTF worth it for indie brands applies to you.

Do advanced features in a DTF gangsheet builder affect DTF gangsheet pricing, and are they worth the higher DTF printing costs?

Features like automatic tiling and color management can raise DTF gangsheet pricing, but they often save time and reduce waste. If the savings exceed the price premium over your production cycles, they are worth considering.

How can I estimate ROI from DTF gangsheet pricing for small runs?

Start with your current DTF printing costs, estimate per-sheet savings from gangsheet layouts, and project monthly volumes. Track actual waste, time, and materials to compute payback and compare across different DTF gangsheet pricing tiers.

| Aspect | Key Points |

|---|---|

| What is a DTF gangsheet builder? | A tool that designs, packs, and optimizes multiple designs on a single transfer sheet to maximize throughput and minimize waste, enabling faster prepress and lower per-item costs. |

| Pricing structure | Upfront licenses or subscriptions; per-sheet or per-transfer fees; bundles with printers or RIP software; cloud vs desktop; add-ons affecting total cost. |

| Total cost of ownership (TCO) | Includes upfront fees, maintenance, hardware, consumables, labor, waste, and onboarding time over 12–36 months. |

| What drives pricing? | Features like automatic tiling, color management, bleed control; workflow integrations; multi-user licenses; support; hardware bundles. |

| DTF costs versus gangsheet pricing | Per-sheet costs decrease with efficient gangsheet usage; high upfront cost can be offset by savings on film, ink, and labor for larger runs. |

| Is DTF worth it for indie brands? | Depends on run length, SKU count, color complexity, lead times, and cash flow; ROI hinges on long-term savings. |

| ROI example (summary) | Illustrative: consolidating transfers per sheet reduces film waste and per-transfer cost, shortening payback depending on run size and design complexity. |

| Choosing the right tool | Compatibility with printer/RIP, ease of onboarding, scalable licensing, and active support/community. |

| Practical tips to optimize costs | Plan ahead with templates, maintain color consistency, run small tests, use efficient materials, track ROI over time. |

Summary

DTF gangsheet builder pricing is a critical factor in evaluating the economics of indie-brand DTF production. It’s not just upfront costs or per-sheet prices; it’s how well the tool integrates with your workflow, reduces waste and labor, and accelerates time to market for new designs. For brands with steady or growing output, and designs that benefit from packing multiple prints onto a single sheet, the long-term savings can justify the investment. For very small runs or designs with minimal color complexity, you may prefer a lighter-touch approach or a pay-as-you-go model. The key is to run a thorough cost-benefit analysis, track real-world numbers, and ensure the chosen DTF gangsheet solution aligns with your brand’s growth trajectory and production realities. In short, DTF gangsheet pricing should be evaluated through the lens of value, efficiency, and sustainability of your indie business model, not just the sticker price. If you’re contemplating the jump, start with a clear pilot project: map your current costs, identify the biggest sources of waste, and test how much you can optimize with a gangsheet builder. In many cases, the payoff comes from the combination of smarter layouts, reduced film usage, and a streamlined prepress workflow that frees your team to focus on design, marketing, and growth.