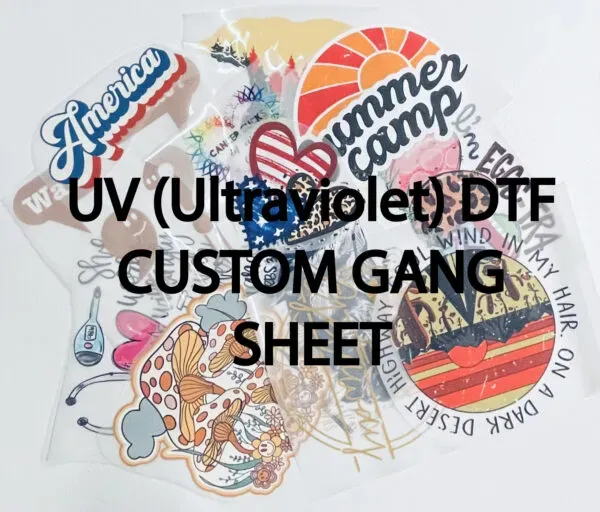

In the innovative realm of graphic design printing, UV DTF Gangheet stands out as a highly effective technique that delivers vibrant and long-lasting results. Leveraging the advantages of the UV printing process, this method integrates Direct-to-Film printing technology to ensure precise color application and detail retention on various substrates. With its unique capabilities, UV DTF Gangheet has rapidly gained popularity among professionals seeking top-tier solutions for custom merchandise, apparel, and signage. This guide will walk you through the essential steps involved in the UV DTF printing process—from the initial design phase to the final curing stage—highlighting the numerous benefits of this modern approach. As you delve into this transformative technology, you’ll discover how UV DTF can elevate your graphic printing game, making it a go-to method for high-quality print production.

Exploring the intricacies of UV Direct-to-Film printing unveils a modern approach to high-quality print production that is immensely valuable in today’s market. Often referred to as DTF printing, this technique utilizes advanced UV printing technology to produce striking and durable designs applicable across a wide array of materials. By combining innovative graphic design printing methods with the efficiency of UV printing processes, users benefit from outstanding output that is both vibrant and resilient. The advantages of DTF printing become evident as it caters to the demands of contemporary designers seeking versatility and quality. This introductory overview sets the stage for a detailed discussion on the step-by-step workflow of this exceptional printing methodology.

Understanding the UV DTF Printing Process

The UV Direct-to-Film (DTF) printing process is a cutting-edge technique that combines traditional printing methods with modern technology. This process begins with the creation of a digital design, which is then printed directly onto a specialized film. Once the design is printed, UV light is used to cure the inks, ensuring that the colors are vibrant and durable. The result is prints that are not just visually stunning but also long-lasting, offering a high resistance to wear and tear.

In addition to durability, the UV DTF printing process allows for exceptional detail and color accuracy. The advanced UV printing technology enables the reproduction of intricate designs with fine lines and gradients, making it ideal for graphic design printing. As businesses increasingly look for ways to stand out, leveraging UV DTF’s capabilities can help create unique and compelling merchandise that captures audience attention.

Key Advantages of UV DTF Printing

One of the primary advantages of UV DTF printing is its remarkable durability. UV-cured inks are less susceptible to fading and abrasion, making them an excellent choice for products exposed to the elements or frequent washing, such as apparel. This longevity translates not only to better quality products but also to higher customer satisfaction and repeat business.

Another significant benefit is the versatility of substrates that UV DTF can print on. Whether you’re printing on fabric, plastic, or even wood, the adaptability of this technique allows for innovative and varied applications. This flexibility makes UV DTF printing an attractive option for businesses looking to diversify their product offerings and cater to different markets.

The Importance of Design in UV DTF Printing

The design phase is pivotal in UV DTF printing, as it sets the foundation for the entire printing process. Graphic designers must consider various factors, such as color profiles and file formats, to ensure that their artwork is compatible with the printing technology. Using programs like Adobe Illustrator, designers can create visually appealing graphics that work seamlessly with UV DTF printers, resulting in brilliant, high-quality outputs.

Effective design also includes understanding the dimensions and resolution needed for print. Ensuring that the design fits the specifications for the chosen substrate is crucial for the success of the project. By investing time in the design process, businesses can elevate their brand identity and produce visually striking prints that resonate with their customers.

Technical Setup for Optimal UV DTF Printing

Successful UV DTF printing hinges on a well-executed print setup. After transferring the design to the printer’s software, adjusting the resolution, ink density, and print mode becomes crucial. These settings can significantly impact the quality and fidelity of the final print. The ability to fine-tune these variables allows for greater control over the printing results, ensuring that the final product meets the desired standards.

Additionally, a proper film loading process is key to achieving successful results in UV DTF printing. Using the correct type of film can greatly influence how inks adhere and yield vibrant colors. Knowing your material is critical, as different films serve distinct purposes and can affect the overall output quality and durability.

Heat Transfer in the UV DTF Workflow

After printing, the heat transfer stage is vital for ensuring that the inks bond correctly to the substrate. This process involves using a heat press to apply specific heat and pressure to achieve optimal ink adhesion, which is essential for long-lasting prints. Understanding the right temperature and pressing duration is crucial, as incorrect settings can lead to poor-quality results or damage to the substrate.

Pre-pressing the garment or item before applying the design can also enhance the final product. This step not only helps to smooth the surface but also removes any moisture, creating a prime environment for the inks to adhere. By prioritizing the heat transfer process, businesses can ensure that their UV DTF products withstand the rigors of use, maintaining their visual appeal over time.

Future Trends in UV DTF Printing Technology

The UV DTF printing landscape is continually evolving, with recent advancements focusing on sustainability and automation. The introduction of eco-friendly inks is a significant step towards reducing the environmental impact of printing processes. These inks provide similar performance characteristics to traditional options, but with a reduced ecological footprint, aligning with the values of many modern consumers.

Automation is also transforming the UV DTF printing industry by streamlining the process, increasing efficiency, and lowering labor costs. Automated systems simplify various tasks, from design uploads to print setups, allowing businesses to focus more on creativity and quality. As technology continues to advance, those engaged in UV DTF printing can expect enhanced capabilities and new opportunities for innovation.

Frequently Asked Questions

What is UV DTF Gangheet and how does it work?

UV DTF Gangheet refers to the UV Direct-to-Film printing process, which uses ultraviolet light to cure inks as they are printed. This technology ensures vibrant colors and precise details by first applying a white ink base before adding colored inks. The cured prints are durable and adhere well to various substrates.

What are the advantages of using UV DTF Gangheet for graphic design printing?

The advantages of UV DTF Gangheet for graphic design printing include high durability, vivid color output, and versatility in printing on various materials. This method allows for detailed and bold graphics that are resistant to fading and wear, making it ideal for custom merchandise and apparel.

How does the UV printing process differ from traditional DTF printing?

The UV printing process, such as UV DTF Gangheet, differs from traditional DTF printing in that it uses UV light to cure inks immediately after application. This leads to faster production times, better adhesion, and more vibrant prints compared to the conventional heat-pressing methods typically seen in traditional DTF printing.

What software is recommended for creating designs suitable for UV DTF Gangheet printing?

For creating designs suitable for UV DTF Gangheet printing, graphic designers typically use software like Adobe Illustrator and CorelDRAW. These platforms support file formats compatible with DTF printers and allow for precise control over color profiles and dimensions.

Is UV DTF Gangheet printing eco-friendly?

Yes, UV DTF Gangheet printing is increasingly becoming eco-friendly, thanks to advancements such as the use of sustainable inks that reduce environmental impact. Additionally, the fast curing process minimizes energy consumption compared to other printing methods.

What types of materials can UV DTF Gangheet prints be applied to?

UV DTF Gangheet prints can be applied to a wide range of materials, including fabrics, plastics, and metals. This versatility makes it an excellent choice for various applications, from clothing to signage and promotional products.

| Step | Key Points |

|---|---|

| 1. Design Creation | – Use software like Adobe Illustrator or CorelDRAW. – Save artwork in PNG or TIFF format. – Work in CMYK color model for accuracy. |

| 2. Print Setup | – Import design to printer software and adjust settings. – Load proper film for printing. |

| 3. UV Printing | – Apply a white ink base layer for vibrancy. – Use UV light to cure inks for durability. |

| 4. Heat Transfer | – Pre-pressing the substrate for adhesion. – Apply heat and pressure with a heat press. |

| 5. Finishing Touches | – Inspect prints for quality. – Consider additional treatments for durability. |

| 6. Final Inspection and Packaging | – Conduct a quality control check. – Package products securely for delivery. |

Summary

UV DTF Gangheet is reshaping the printing landscape with its innovative approach to creating stunning prints. This comprehensive process encompasses everything from the initial design phase to the meticulous printing and finishing stages, ensuring high-quality results that meet modern aesthetic demands. The advantages of UV DTF printing, such as durability and versatility, make it an ideal choice for a wide range of applications in textiles and hard surfaces alike. As technology continues to evolve, the adoption of eco-friendly inks and automation will further enhance the efficiency and sustainability of the UV DTF printing process.