In the realm of textile printing, Gangsheet Builders are revolutionizing the way businesses approach Direct to Film (DTF) printing. This innovative technology allows printers to optimize their print production by combining multiple designs into a single sheet, enabling impressive cost efficiency. With the rising demand for high-quality printing techniques, Gangsheet Builders not only reduce material waste but also enhance the overall performance of print operations. As companies strive for sustainability and efficiency in their printing processes, understanding the remarkable benefits of Gangsheet Builders becomes paramount. Thus, for those in the textile printing industry, adopting this cutting-edge tool could be key to staying ahead in a competitive market.

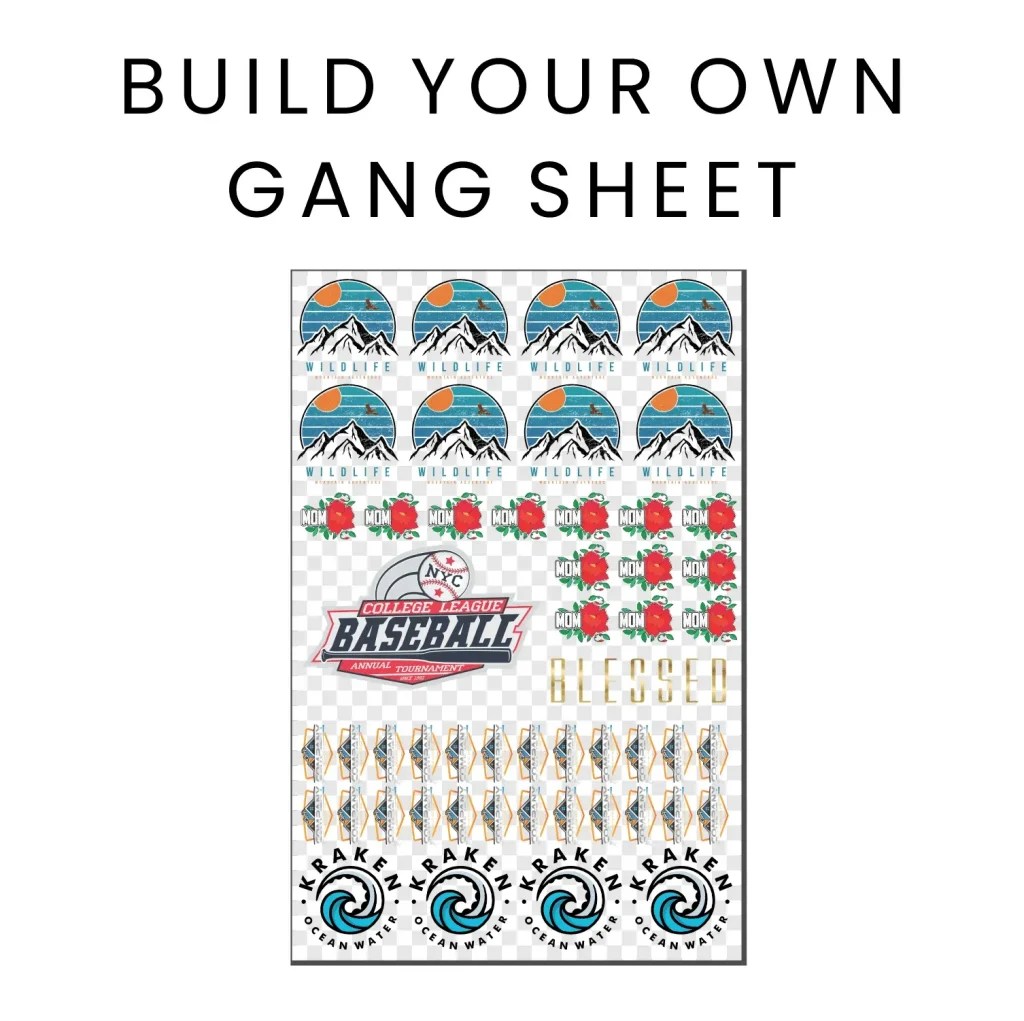

Gangsheet Builders, also known as design aggregation tools, represent a significant advancement in the world of Direct to Film (DTF) printing. These remarkable devices facilitate a streamlined approach to print production, allowing for multiple artworks to be consolidated onto a single film sheet. This method not only boosts cost efficiency but also minimizes waste, creating a more sustainable environment for printing operations. As printing businesses increasingly look to optimize their processes, the adoption of gangsheet techniques is becoming essential for maintaining a competitive edge. By leveraging such innovative solutions, companies can enhance productivity while delivering high-quality textile products that meet the diverse demands of their clientele.

Understanding the Mechanics of DTF Printing

DTF printing, or Direct to Film printing, utilizes a unique process where designs are printed onto a specialized film. This film is coated with a heat-resistant layer that enables vibrant ink adhesion and rich color reproduction. With DTF’s increasing popularity in the textile printing industry, it allows for high-quality outputs that were traditionally difficult to achieve with older printing techniques. The simplified process makes it accessible for businesses aiming to expand their custom apparel offerings, further enhancing its role in today’s competitive market.

The essence of DTF printing is its ability to transfer images directly from the film onto various fabrics, using heat and pressure to achieve a flawless bond. This technique not only delivers exceptional print quality but also a level of detail that appeals to designers. When combined with advanced technologies such as gangsheet builders, the efficiency of DTF printing is significantly enhanced, allowing for maximization of both time and resources in a fast-paced production environment.

Frequently Asked Questions

What are gangsheet builders used for in DTF printing?

Gangsheet builders are specialized tools used in DTF (Direct to Film) printing to combine multiple designs into a single sheet of film, known as a gang sheet. This method maximizes production efficiency and significantly reduces material waste, making it an essential component for businesses in textile printing.

How do gangsheet builders enhance cost efficiency in printing?

Gangsheet builders enhance cost efficiency by allowing printers to print multiple designs on a single sheet, thereby lowering the costs of ink and film materials. This technique accelerates the overall production process, enabling businesses to manage larger orders while maintaining tighter profit margins.

What sustainability benefits do gangsheet builders offer for textile printing?

Gangsheet builders promote sustainability in textile printing by minimizing material waste. By utilizing the entire sheet of film effectively, these builders help businesses reduce leftover materials, aligning with eco-friendly practices that appeal to both customers and stakeholders in the industry.

Can gangsheet builders improve productivity in DTF printing operations?

Yes, gangsheet builders significantly improve productivity by allowing printers to print several designs simultaneously. This streamlining of processes reduces the number of setups required for different prints, thus enhancing turnaround times and enabling businesses to handle more jobs efficiently.

What types of products can be created using gangsheet builders in DTF printing?

Gangsheet builders enable the production of a wide variety of products, including customized apparel and merchandise. Their versatility allows businesses to cater to diverse fabric types and designs within one print cycle, expanding product offerings and appealing to a broader customer base.

Are gangsheet builders user-friendly for those new to DTF printing?

Many modern gangsheet builders are equipped with intuitive software designed to simplify the design-to-print process. This user-friendliness makes it easier for newcomers to the DTF printing industry to arrange, optimize, and size their designs correctly, reducing barriers to entry and facilitating the process for new businesses.

| Key Points | Description |

|---|---|

| What is DTF Printing? | A modern printing method involving designs printed onto a coated film and heat transferred onto fabric, known for vibrant colors and high quality. |

| Gangsheet Builders | Tools that allow multiple designs to be printed on a single sheet of film, improving efficiency and reducing setup costs. |

| Cost Efficiency | They significantly lower costs by saving on materials and accelerating the production process. |

| Reduced Waste | Minimizes unused material and promotes sustainable practices, appealing to eco-conscious customers. |

| Increased Productivity | Enables simultaneous printing of designs, leading to faster order completion and better workflow. |

| Versatility | Compatible with various fabrics, allowing businesses to produce diverse products in one print cycle. |

| User-Friendly Software | Modern gangsheet builders include intuitive software, making design arrangement simple even for beginners. |

| Industry Trends | Growing adoption of gangsheet techniques by DTF printers and innovations in software for layout optimization. |

Summary

Gangsheet Builders are revolutionizing the DTF printing landscape, providing significant advantages for businesses in the textile printing industry. These tools not only enhance operational efficiency by consolidating multiple designs into a single print but also offer cost savings, reduced material waste, and increased productivity. With their user-friendly software and compatibility with various fabrics, Gangsheet Builders facilitate a seamless transition into the world of customized printing. As the industry continues to evolve, adopting these innovative solutions is key for companies aiming to stay competitive and environmentally conscious in a market that’s ever-demanding high-quality prints.