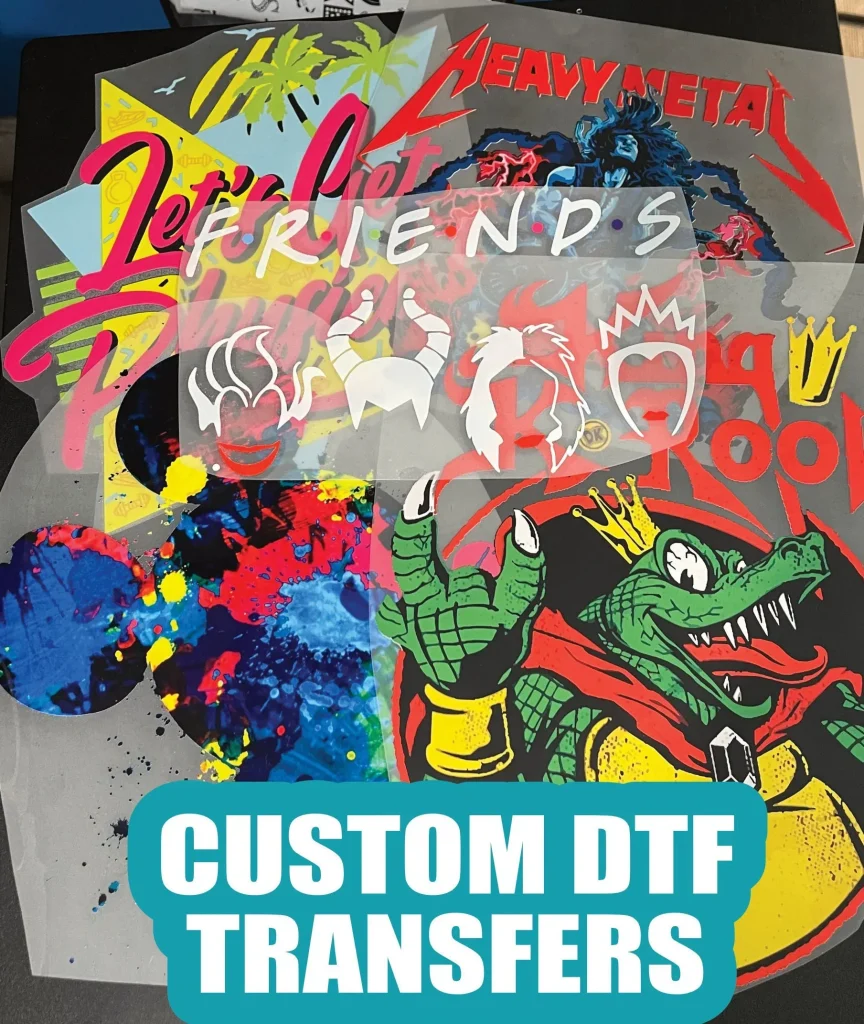

DTF transfers, or Direct-to-Film transfers, have significantly altered the landscape of custom garment printing, offering an innovative solution for creating bold, high-quality designs. This print method combines vibrant colors and exceptional durability, making it a favorite among entrepreneurs and established businesses alike. Understanding the DTF printing process, along with effective heat transfer tips, is essential for optimizing results and minimizing common pitfalls. In this guide, we will explore invaluable DTF printing tips that ensure perfect prints every time, enabling creators to take their apparel designs to the next level. So, if you’re eager to master the art of DTF transfers, read on for expert insights and practical advice.

Also known as Direct-to-Film printing, DTF transfers represent a cutting-edge technique within the realm of custom apparel design. This method enables creators to transfer intricate and colorful designs onto garments through a specialized printing process. As businesses seek to enhance their offerings, understanding the nuances of DTF printing is vital for achieving professional results. The process involves key elements such as optimal settings for heat transfer and selecting quality materials, which are crucial for success. By honing these skills, designers can elevate their craft and deliver stunning prints that resonate with their clients.

Understanding the DTF Transfer Process

The Direct-to-Film (DTF) transfer process is a breakthrough technique in custom garment printing that blends digital printing with heat transfer technology. Initially, a design is printed onto a special film using specific DTF inks, which are formulated to create vibrancy and durability. After printing, an adhesive powder is applied while the ink is still wet, creating a strong bond that ensures the print adheres well during the heat transfer process. This method allows intricate designs and vivid colors to be printed with minimal risk of fading, making DTF an attractive option for businesses and consumers alike.

Once the design is ready and the adhesive is added, the film is then placed onto the desired fabric and subjected to heat and pressure using a heat press. This step activates the adhesive and transfers the design onto the material. It’s crucial to follow the recommended temperature and duration guidelines for an effective transfer; typically, this involves setting the heat press to around 320°F (160°C) for 15 to 20 seconds. Mastering the DTF transfer process grants garment printers the ability to produce high-quality, long-lasting prints that can withstand frequent washing.

Essential Tips for DTF Printing Success

Achieving success in DTF printing requires a solid understanding of optimal printer settings and material selection. One of the essential tips is to maintain high saturation levels for color vibrancy, which can dramatically improve the overall aesthetic of the final product. Additionally, adjusting print speed can significantly contribute to the quality of the transfer; slower speeds allow for better ink deposition and reduce the risk of misprints. By fine-tuning these settings, printers can ensure that every DTF transfer looks professional and visually striking.

Moreover, the quality of the materials used directly impacts the performance of DTF printing. Utilizing professional-grade DTF films and inks is paramount to achieving a strong bond and vibrant colors in the final product. Reputable brands such as Pillow Printing offer specially designed inks that complement the DTF process efficiently. By investing in quality materials, printers not only enhance durability but also reduce the common pitfalls associated with poor material choices, further elevating their craft in the custom garment printing arena.

Design Preparation for Flawless DTF Prints

Design preparation is a critical stage in the DTF printing process that can make or break the final result. Before sending a design to print, it’s crucial to check that all files are in the correct color space, either RGB or CMYK, to ensure the colors transfer accurately onto the fabric. Additionally, mirroring the design before printing is an essential step that often goes overlooked; since DTF transfers are applied in a reverse format, failing to mirror can result in reversed graphics that spoil the intended look of the garment.

Using professional software tools to prepare designs can save time, enhance precision, and avoid trial-and-error mistakes. Engaging with the community, such as Reddit’s Printmaking group, can provide invaluable insights and tips for professionals, helping them refine their design practices. By focusing on these design preparation techniques, printers can achieve exceptional results that showcase their creativity and technical skills.

Optimizing Heat Transfer Techniques

The heat transfer process is undoubtedly one of the most vital factors in DTF printing success. Using the correct temperature and pressure settings ensures that the adhesive bonds well to the fabric, preventing issues like lifting or fading. It is essential to follow the recommended guidelines closely, typically applying heat at around 320°F (160°C) for approximately 15 to 20 seconds. Monitoring these factors can drastically improve the adherence and vibrancy of the transferred design, ultimately leading to high-quality finished products.

Incorporating heat transfer best practices is helpful for both novice and experienced users alike. It’s ideal to invest in a reliable heat press that can maintain consistent temperatures and even pressure across the transfer. Many resources, such as Heat Transfer Warehouse, offer advice on optimizing heat settings and methodologies specific to different materials. By perfecting the heat transfer technique, printers can ensure the longevity and vibrancy of DTF prints, providing customers with products they will love.

Post-Transfer Care Strategies

Post-transfer care is a crucial aspect of maintaining the quality of DTF prints. After a transfer is applied, it is essential to allow the printed garment to cool adequately before handling it. Rushing this step can lead to smudging or peeling, ultimately compromising the print quality. A common best practice is to wait at least 24 hours before any washing or aggressive handling to allow the adhesive to cure properly.

Furthermore, conducting a wash test after allowing the print to cure is an excellent approach to evaluating the durability of the transfer. This involves washing the garment in a gentle cycle to see how well the design holds up against fraying and fading. Many YouTube channels have informative guides on proper post-care techniques that can enhance the washability of DTF prints. By implementing careful handling and regular testing, printers can ensure that their products remain vibrant and durable for long-term enjoyment.

Latest Trends in DTF Printing Technology

The landscape of DTF printing is continually evolving, with recent trends focusing on sustainability and quality enhancements. Eco-friendly inks are gaining popularity as more manufacturers, such as Vivid Color, prioritize environmentally responsible options that deliver vibrant results without harming the planet. This shift not only caters to consumer demands for greener products but also opens new avenues for businesses to market their services, appealing to a broader audience.

Additionally, innovations in printer technology are making it easier for businesses to adopt DTF processes. Major brands like Epson and Roland are introducing specialized printers that significantly reduce setup time and improve print quality. Staying informed about these advancements can provide printers with a competitive edge in the market. Understanding emerging trends in DTF technology ensures that businesses can adapt and thrive in the fast-paced world of custom garment printing.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film which is then transferred to fabric using heat and pressure. This process allows for vibrant colors and high detail, making it ideal for custom garment printing.

What materials are required for successful DTF printing?

To achieve high-quality DTF prints, you’ll need high-quality DTF films and specially formulated inks designed for DTF printing. Using polyethylene-based films can improve transfer quality and durability for custom garment printing.

What are the key DTF printing tips for optimal results?

For the best results in DTF printing, ensure your printer settings are optimized for color saturation and speed. Additionally, always mirror your designs before printing and follow correct heat transfer procedures to ensure adherence.

How do you optimize the heat transfer process in DTF printing?

In DTF printing, the heat transfer process is crucial. Set your heat press to approximately 320°F (160°C) and transfer for 15 to 20 seconds. Proper temperature and duration are critical to ensuring the DTF transfer adheres correctly to the fabric.

What is the best way to care for DTF prints after transfer?

After applying a DTF transfer, let it cool for at least 24 hours before washing. This allows the adhesive to cure. Conducting a wash test will help determine the durability of the transfer and ensure the quality of the print.

What trends are currently shaping the DTF printing market?

Recent trends in the DTF printing market include advancements in eco-friendly inks and specialized printers aimed at improving efficiency and print quality. Staying updated on these trends helps enhance your DTF printing capabilities.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfers | DTF transfers provide vibrant colors and durability, revolutionizing custom garment printing. |

| Quality Materials | High-quality DTF films and inks crucial for adherence and color accuracy. |

| Printer Settings | Adjust color saturation and print speed for optimal results. |

| Design Preparation | Ensure correct color space and mirror designs before printing. |

| Heat Transfer Process | Optimal temperature at 320°F and duration of 15-20 seconds is critical. |

| Post-Transfer Care | Allow 24 hours for curing and conduct wash tests for durability. |

| Recent Trends | Innovations in eco-friendly inks and specialized printers enhance DTF capabilities. |

Summary

DTF transfers have emerged as a transformative technology in the custom garment printing industry, characterized by vibrant colors and lasting durability. By prioritizing quality materials, optimizing printer settings, and mastering the heat transfer process, businesses can ensure superior print results. Moreover, understanding post-transfer care and staying abreast of recent trends in eco-friendly inks and advanced printing technology enhances the overall effectiveness of DTF transfers. Embracing these practices not only elevates print quality but also positions businesses competitively in a growing market.