In the world of T-shirt printing technology, **DTF transfers** are rapidly gaining recognition as a game-changing method that blends innovation with sustainability. Direct-to-Film printing is not only efficient but also versatile, providing businesses with tailored printing solutions that meet modern demands. As consumers increasingly seek customized apparel, DTF’s ability to deliver vibrant and high-quality prints makes it the go-to option in the industry. This sustainable printing method minimizes waste and energy consumption, aligning perfectly with the growing trend towards eco-friendly practices. In this article, we will explore the numerous benefits of DTF and why it is heralded as the future of apparel production.

Commonly referred to as Direct-to-Film printing, DTF transfers are quickly becoming a popular choice in the realm of customized clothing production. This innovative T-shirt printing technology offers a range of benefits, including impressive print quality and reduced environmental impact, which are vital in today’s market. As brands seek sustainable printing alternatives, the capability to efficiently produce personalized designs with minimal waste makes DTF an attractive solution. With the rise of customizable apparel, this printing method stands out as an effective way to meet the diverse needs of consumers. Embracing DTF technology could very well define the future landscape of the textile industry.

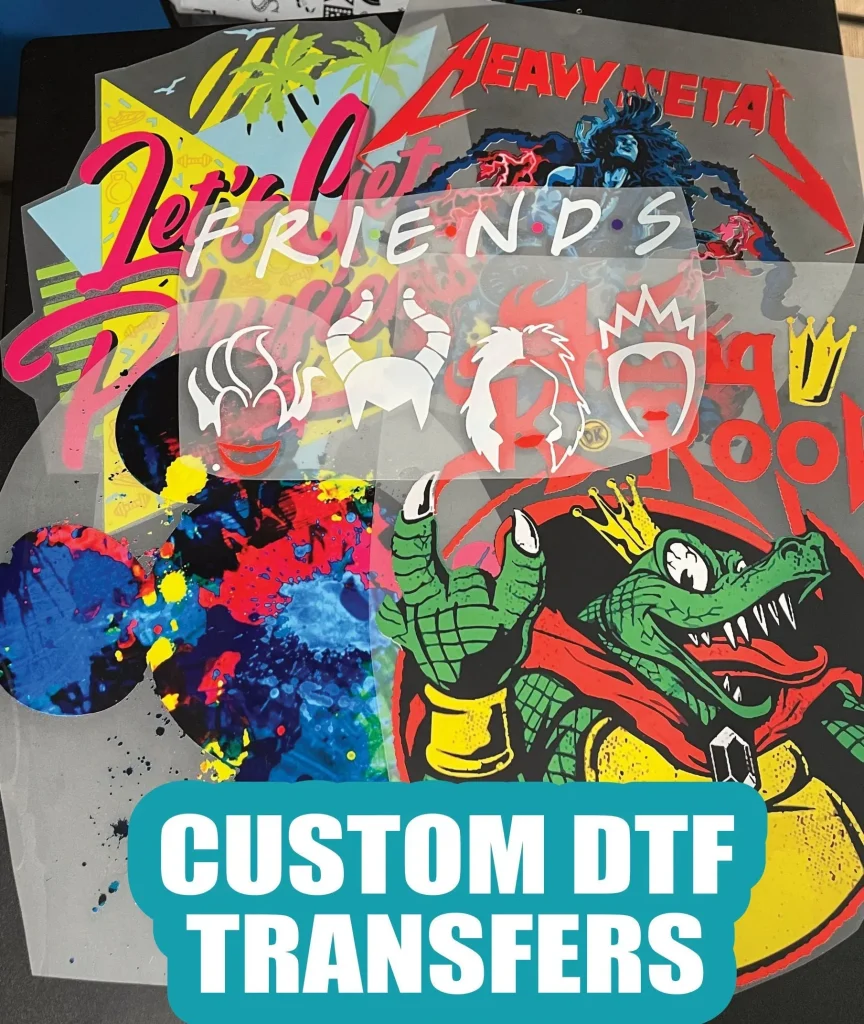

The Advantages of DTF Transfers for T-Shirt Printing

DTF transfers bring numerous advantages to the realm of T-shirt printing, positioning themselves as a preferred method for businesses looking to innovate. The ability to produce high-quality prints on-demand allows brands to minimize inventory costs while still catering to diverse customer preferences. Unlike traditional printing methods, which often require large quantities to justify setup costs, DTF technology enables smaller runs without sacrificing print quality or increasing waste. This shift not only enhances profitability but also aligns with modern consumer desires for customization.

Moreover, DTF transfers excel in producing accurate and vibrant designs that stand out in a crowded marketplace. The technology supports intricate prints, offering high detail and clarity regardless of the color complexity. This ability to accommodate a wide range of design specifications makes DTF an ideal choice for brands aiming to differentiate their offerings with unique and personalized apparel.

Frequently Asked Questions

What are DTF transfers and how do they work in T-shirt printing?

DTF transfers, or Direct-to-Film transfers, are a cutting-edge T-shirt printing technology where designs are printed onto a special film and then heat-pressed onto fabric. This method eliminates the need for screens and setups, making it an efficient and eco-friendly alternative to traditional printing techniques.

Why should businesses choose DTF transfers over traditional printing methods?

Businesses should opt for DTF transfers because they offer operational efficiency, sustainability, and versatility. DTF printing minimizes waste by allowing precise order quantities, requires no water during production, and provides vibrant and durable prints, making it suitable for customized apparel across various fabric types.

How do DTF transfers contribute to sustainable printing practices?

DTF transfers contribute to sustainable printing by significantly reducing material waste and avoiding water pollution, which are common issues with traditional methods like screen printing. By choosing DTF technology, businesses can lower their environmental impact while meeting the demands of eco-conscious consumers.

Can DTF transfers be used for custom apparel production?

Yes, DTF transfers are ideal for custom apparel production. The technology allows for on-demand printing and detailed designs, enabling businesses to create unique, personalized items efficiently. This flexibility supports small businesses and independent creators looking to tap into niche markets.

What are the quality benefits of using DTF printing solutions?

DTF printing solutions provide high-quality outputs characterized by vibrant colors and durability. This technology excels in producing detailed and multicolored designs, making it suitable for a wide range of apparel applications, from everyday T-shirts to intricate promotional clothing.

How do DTF transfers support small businesses and crafters?

DTF transfers support small businesses and crafters by offering affordable and flexible printing solutions. This technology lowers the barrier to entry for independent creators, allowing them to produce custom items without the substantial overhead costs of mass production, thus fostering creativity and entrepreneurship.

| Key Points | Details |

|---|---|

| Sustainability and Waste Reduction | DTF printing minimizes material waste, requires no water, and reduces excess inventory, making it eco-friendly compared to screen printing. |

| Operational Efficiency | DTF enables on-demand production, reducing setup times and errors while saving energy compared to traditional methods. |

| Quality and Versatility | Produces vibrant, high-quality prints on various fabrics, suitable for diverse applications and supporting customization trends. |

| Support for Small Businesses | DTF offers affordable solutions, allowing small businesses and independent creators to thrive with lower production costs. |

Summary

DTF transfers are revolutionizing T-shirt printing by offering sustainable, efficient, and versatile solutions that significantly reduce waste and production costs. As the demand for high-quality, customizable designs grows, DTF technology presents a unique opportunity for businesses to align with modern consumer values, particularly in eco-friendliness. The operational advantages of DTF printing also empower small businesses to enter the market with lower financial barriers, fostering entrepreneurship and creativity. As more brands implement DTF transfers, the apparel industry is likely to see a shift towards more sustainable practices and innovative designs, solidifying DTF’s role as a leader in the future of T-shirt printing.