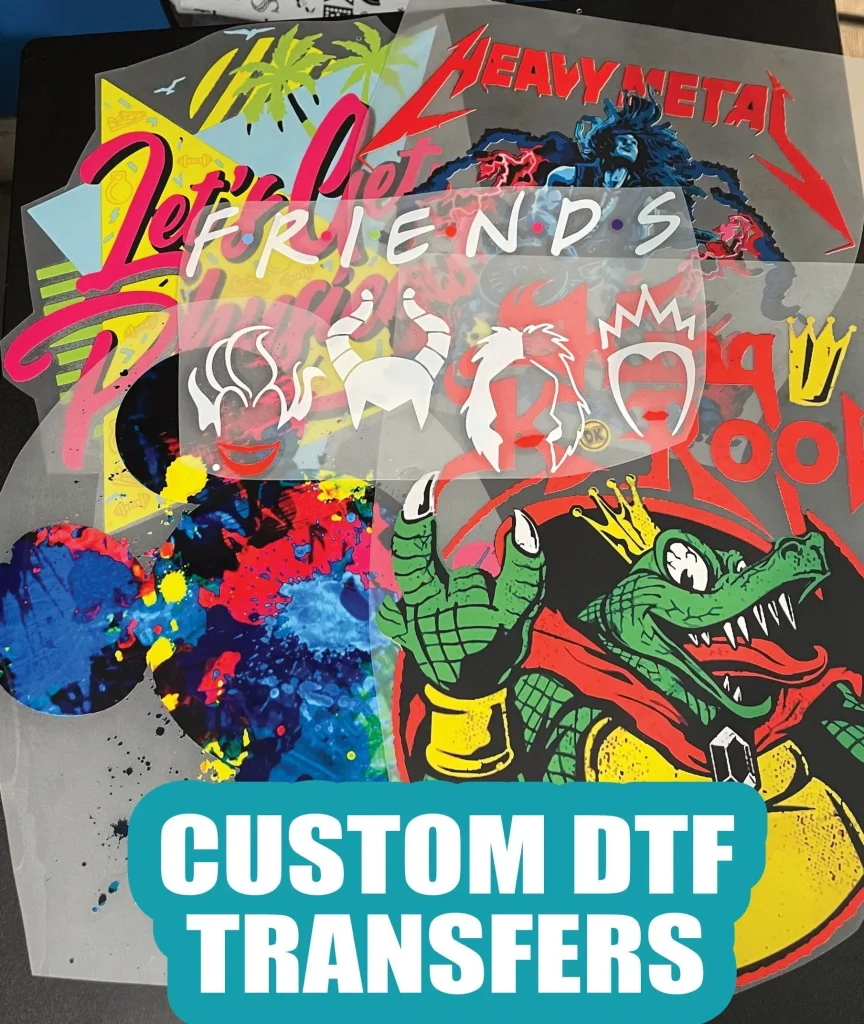

In the vibrant world of textile printing, DTF transfers (Direct to Film transfers) have emerged as a game-changer, offering unmatched flexibility and high-quality results. These specialized transfers utilize a unique process that allows for the application of intricate designs onto various fabrics, making them a favorite among both hobbyists and professionals alike. Understanding how to achieve flawless DTF transfers is essential for anyone looking to elevate their printing game and ensure customer satisfaction. In this guide, we will dive deep into the DTF transfer process, discussing proven DTF printing tips that can significantly improve your outcomes. Get ready to unlock the secrets of achieving vibrant, long-lasting prints with expert techniques that will set you apart in the custom apparel industry.

DTF printing, or Direct to Film printing, represents an innovative approach to the world of garment decoration. By leveraging unique film transfer technology, creators can effectively apply their desired designs onto fabrics with impressive durability and vibrancy. This article aims to unravel the complexities of the DTF transfer process, shedding light on best practices and techniques that can lead to outstanding results. Whether you’re brand new to the craft or seeking advanced DTF printing tips, understanding the nuances of this method will empower you to create stunning apparel. Join us as we explore the essentials of mastering the art of DTF transfers, ensuring every piece you produce carries optimal quality and appeal.

The Importance of Quality Materials in DTF Printing

When embarking on the journey to master DTF printing, selecting high-quality materials is your foundation. The type of DTF film you choose can greatly influence the final output. Films specifically designed for Direct to Film printing ensure that your designs vividly transfer to fabric with excellent durability. Experimenting with different brands can help you discover which products yield the bright, vibrant colors you seek in your final prints.

Additionally, the inks you use play a pivotal role in achieving flawless DTF transfers. High-quality, DTF-compatible inks deliver superior color vibrancy and longevity, ensuring that your designs withstand the test of time. Investing in reputable ink brands not only helps in achieving cleaner transfers but also contributes to maintaining a professional standard in your custom apparel business.

Optimizing Printer Settings for DTF Transfers

The printer settings you utilize can drastically alter the quality of your DTF transfers. For optimal results, it’s essential to set your printer to a high resolution, ideally at 300 dpi, which results in crisp details and vibrant outputs. Moreover, adjusting the ink density is crucial; too much ink can lead to smudging, while too little may cause faded designs. A balance in print speed—slower speeds usually produce sharper and more saturated images—is also worth considering.

Furthermore, ensuring that your printer is well-maintained enhances its performance. Regularly cleaning printheads and ensuring that ink cartridges are filled with quality inks is essential. Calibration checks should also be part of your routine to maintain consistency in print quality across different batches of DTF transfers.

Pre-Treatment Techniques for Fabrics

Proper pre-treatment of fabrics is a game-changer when it comes to achieving flawless DTF transfers. Fabrics, especially cotton, often behave differently with inks, and pre-treatment solutions can create a better bonding surface for the transfer. By applying pre-treatment sprays, you tailor the fabric’s surface, making it more receptive to the DTF transfer—an essential step for ensuring the longevity and vibrancy of your designs.

Additionally, understanding the properties of different fabrics aids in optimizing pre-treatment methods. For instance, synthetic fibers may require less treatment compared to natural fibers. It’s important to experiment with various pre-treatments to see how they affect ink absorption and adhesion, guiding you to the best practices for various clothing substrates.

Mastering Heat Pressing Techniques

Achieving flawless DTF transfers is largely dependent on mastering the heat pressing technique. Precisely controlling the temperature and pressure during the transfer is crucial; settings typically range from 305°F to 320°F with consistent pressure being vital. Overheating can damage the transfer while insufficient pressure can lead to incomplete adhesion. Careful calibration based on your specific materials ensures that each transfer emerges in pristine quality.

Moreover, timing is another critical element in the heat pressing equation. Following manufacturer recommendations for timing can prevent common pitfalls that affect the durability of your prints. Overexposure might ruin the design, while inadequate pressing time may cause the transfer to peel off after initial washes. Keeping a checklist of the ideal settings for different fabric types can streamline your process for creating durable DTF outputs.

Post-Press Cooling and Curing Techniques

After your DTF transfers are applied, giving ample time for cooling is essential to preserve the integrity of the transfers. Allowing the design to cool down for at least 10-15 seconds on a cooling surface helps prevent tearing or incomplete adhesion. This step might seem minor but can dramatically impact the durability and appearance of the finished product.

In addition to cooling, proper curing techniques cannot be overlooked. For water-based inks, curing the transfers ensures that colors bond well with the fabric, enhancing their longevity. Utilizing a curing oven or repeated heat pressing can seal the design effectively, making your transfers resistant to fading and washing. Adopting these methods will help in producing quality workmanship consistently.

Experimenting for DTF Printing Success

Embracing experimentation within the DTF printing process can lead to unexpected improvements and discoveries. Each fabric may respond uniquely to the DTF transfer process, which means that testing different combinations of heat settings, ink densities, and pressure levels can yield insights that elevate your prints from good to extraordinary. Documenting the results of your experiments also facilitates future projects, helping you streamline your DTF transfer workflow.

Furthermore, engaging with fellow DTF printing enthusiasts through community forums allows for the exchange of ideas and techniques. Learning from others’ successes and failures can inspire your experimentation process. Whether you discover a new method or learn a trick to avoid common pitfalls, collaborating with a community can enhance your understanding and application of DTF printing.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs onto a special film using DTF-compatible inks. The printed film is then heat-pressed onto garments, allowing for vibrant, high-quality prints that adhere effectively to various fabric types.

What are some essential DTF printing tips for beginners?

Beginner DTF printing tips include using quality materials, adjusting printer settings for optimal results, ensuring fabric pre-treatment, perfecting heat pressing techniques, and experimenting with different fabrics to find the best settings for each.

What is the DTF transfer process?

The DTF transfer process involves printing on DTF film with specialized inks, heat pressing the film onto fabric, and allowing proper cooling to achieve the best adhesion and durability of the design on the garment.

How do I achieve flawless DTF transfers?

Achieving flawless DTF transfers requires quality materials, correct printer settings (like resolution and ink density), proper heat press settings (temperature, pressure, time), and allowing transfers to cool adequately before peeling.

Why is fabric pre-treatment important for DTF transfers?

Fabric pre-treatment is crucial for DTF transfers as it improves ink adhesion, especially on cotton and other absorbent fabrics. It helps create a suitable surface for the ink to bond effectively, resulting in more durable prints.

What should I consider for curing DTF transfers?

For proper curing of DTF transfers, especially those using water-based inks, additional heat pressing or using a curing oven may be necessary after the initial transfer. This ensures the design sets correctly, enhancing longevity.

| Key Points | Details |

|---|---|

| Understanding DTF Transfers | DTF, or Direct to Film, uses specialized film and inks to produce high-quality prints that adhere well to various fabrics. |

| Quality Materials Matter | Using high-quality DTF film and inks is essential for vibrant and durable transfers. |

| Printer Settings | Optimal settings like 300 dpi for resolution, adjusted ink density, and slower print speed improve print quality. |

| Pre-treatment of Fabrics | Pre-treat fabrics, especially cotton, to enhance ink adhesion during transfers. |

| Heat Pressing Techniques | Correct temperature (305°F-320°F), pressure, and timing are crucial for successful transfers. |

| Cooling Process | Allow 10-15 seconds of cooling after heat pressing to avoid damage. |

| Curing for Longevity | Water-based inks may require additional curing after heat application. |

| Experimentation | Testing different settings and materials can reveal the best practices for unique projects. |

| Bonus Tips | Maintain a clean workspace, follow tutorials, and engage with DTF communities for continuous learning. |

Summary

DTF transfers are an innovative method in the textile printing industry that require attention to detail and a good understanding of the process to achieve flawless results. By utilizing high-quality materials, optimizing printer settings, and mastering heat pressing, you can significantly improve the performance and longevity of your DTF transfers. It’s essential to treat each fabric individually and continuously experiment to find the best methods tailored to your needs. Engaging with the DTF community also fosters growth and insight, providing fresh perspectives to enhance your craftsmanship. Ultimately, with dedication and practice, anyone can excel in the art of DTF transfers.