DTF transfer troubleshooting is a practical guide designed to help printers, crafters, and small businesses achieve reliable results with Direct-to-Film transfers. If you’ve ever worried about misaligned designs, faded colors, or peeling after washing, you’re not alone. This article shows how most DTF transfer issues can be diagnosed and fixed with a systematic approach. By understanding problem patterns and applying the right steps, you can minimize wasted prints, reduce turnaround times, and increase customer satisfaction. It also covers common DTF transfer issues, color fidelity, and practical fixes to achieve durable, production-ready results.

Thinking of this topic through alternative terms aligns with Latent Semantic Indexing: you might frame it as DTF printing problems, DTF transfer problem-solving, or adhesion and color-accuracy challenges in your workflow. Additional LSIs include understanding color management, powder adhesion, misregistration, fabric compatibility, film quality, and cure processes. This lens helps you connect related ideas such as how to fix DTF transfers, DTF ink troubleshooting, and preventing peeling after washing. In short, the discussion mirrors the same goal—reliable, consistent transfers—by exploring symptoms, causes, and practical fixes across related concepts.

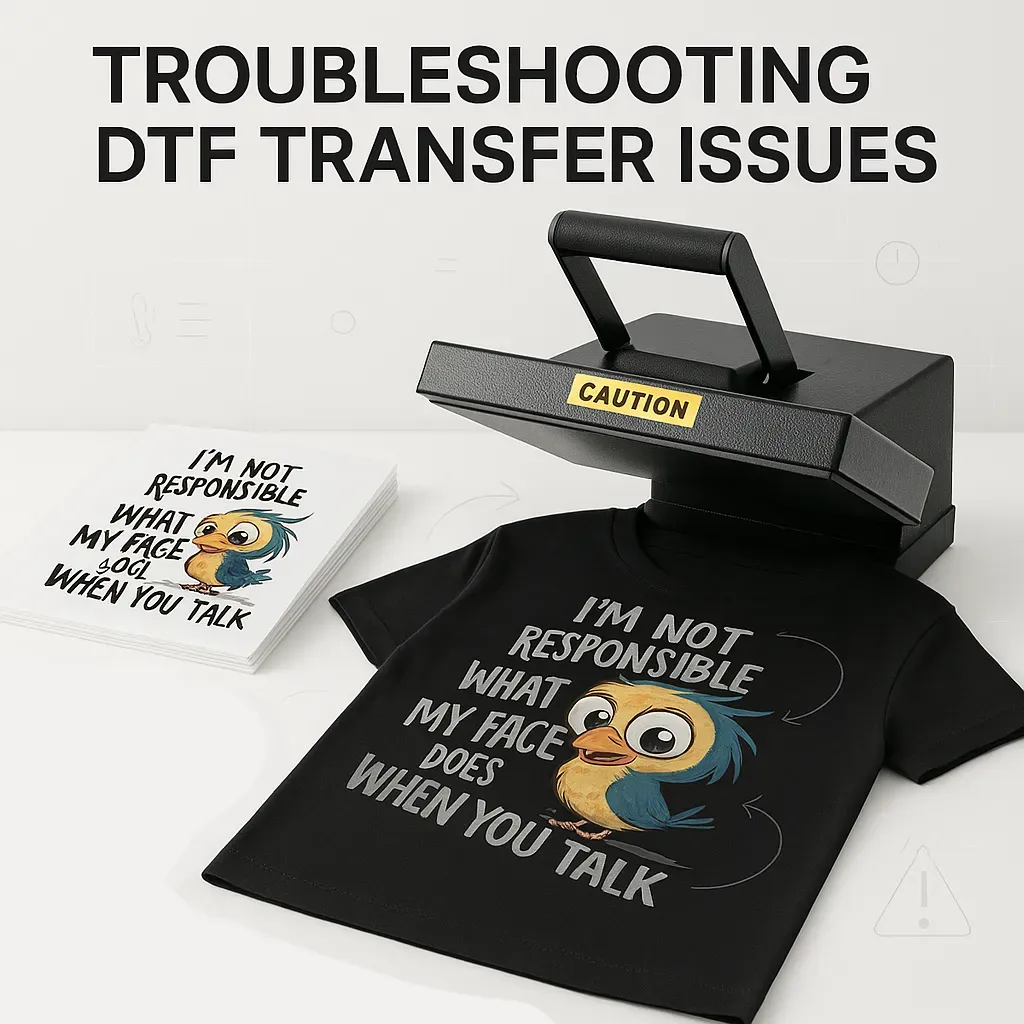

DTF transfer troubleshooting for production-grade results

DTF transfer troubleshooting is a practical framework that helps printers, crafters, and small businesses achieve reliable, production-ready results. When misalignments, faded colors, or peeling after washing crop up, a structured approach can quickly reveal the root cause and the right fix. Using a repeatable process reduces guesswork and supports consistent quality across runs.

This approach emphasizes starting with the basics—proper file preparation, accurate printer calibration, and heat-press settings tailored to the chosen substrate. By controlling variables early in the workflow, you can minimize surprises during transfer, making it easier to diagnose issues and implement durable solutions. Embracing this mindset is what separates DIY misprints from professional-grade results.

Understanding common DTF transfer issues and their root causes

There are several broad categories of problems you’re likely to encounter with DTF transfers: color and image fidelity issues, adhesion and durability problems, and mechanical or alignment challenges. These categories frame the discussion around the most impactful pain points and help you prioritize fixes.

Within each category, specific symptoms illuminate likely causes. For example, color fidelity problems can manifest as color shifts or ghost images, adhesion issues show up as peeling after washing or cracking, and alignment problems appear as misregistration or transfer marks. Understanding these patterns helps you map symptoms to actionable, repeatable remedies.

Diagnosing DTF printing problems across fabrics and designs

DTF printing problems often vary by fabric type, weave, and garment construction. The same design can behave differently on cotton, blends, or synthetic fabrics, which means diagnostics must account for substrate variability. Recognizing this helps you avoid chasing a one-size-fits-all solution and instead tailor fixes to the material at hand.

A practical diagnostic approach combines control checks with systematic testing. Start with color management, ensuring the design is correctly sized and color profiles align with the printer’s capabilities. Next, validate imaging and curing steps, then assess powder application and film quality. This stepwise method makes it easier to pinpoint where the workflow diverges from the desired outcome.

How to fix DTF transfers: a repeatable workflow for reliable outcomes

How to fix DTF transfers begins with a repeatable workflow that you can apply to most projects. A well-documented process reduces variables and speeds up problem solving, especially when you’re managing multiple designs or clients. This mindset focuses on incremental adjustments that yield measurable improvements.

Key steps include verifying print data, calibrating the printer, and validating powder application before any transfer. Conduct controlled tests on swatches to evaluate adhesion, color, and alignment, then iterate by adjusting one variable at a time—such as temperature, time, or pressure—and re-testing. This disciplined approach converts troubleshooting into a predictable, scalable practice.

DTF ink troubleshooting: preserving color, opacity, and consistency

DTF ink troubleshooting centers on maintaining color fidelity, opacity, and print stability. Ink quality directly influences how well colors reproduce and how predictably prints behave under heat and on different fabrics. Regular checks help prevent color drift and inconsistent saturation across batches.

Practical measures include routine nozzle checks, using compatible inks designed for DTF workflows, and storing inks under optimal conditions to prevent thickening or settling. Calibrating printer temperatures and pressure settings to match the chosen ink and film also supports consistent results, reducing reprints and waste while preserving vibrancy.

Preventive maintenance and best practices to minimize DTF transfer failures

Preventive maintenance creates a foundation for reliable transfers. Establishing a standard operating procedure (SOP) for file preparation, printing, powder handling, curing, and pressing reduces variability and prevents common mistakes from creeping into production. A controlled environment further stabilizes performance by mitigating humidity and temperature fluctuations that impact powder adhesion and film behavior.

Beyond process discipline, regular equipment upkeep and documentation are essential. Schedule routine printer maintenance, track effective settings for different substrates, and invest in reliable consumables—film, powder, and software that work well together. Keeping a running log of successful configurations helps you reproduce quality quickly and scale operations with confidence.

Frequently Asked Questions

What is DTF transfer troubleshooting and why is it essential for reliable results?

DTF transfer troubleshooting is a practical, repeatable process that helps you diagnose and fix issues in DTF transfers. By focusing on file prep, printer calibration, powder curing, film quality, and heat-press settings, you can reduce misalignment, color problems, and adhesion failures, achieving consistent, durable results.

What are the most common DTF transfer issues, and how can DTF transfer troubleshooting fixes address misalignment?

Common DTF transfer issues include misalignment, color shift, and adhesion problems. Fixes include verifying design alignment, calibrating the printer, ensuring proper powder application and curing, inspecting the transfer film for defects, and setting correct heat-press parameters; run a small test print to confirm before production.

How can I address DTF printing problems that lead to color shift or faded images?

Start with color management: confirm ICC profiles and color settings, calibrate the printer, and verify ink health. Ensure proper film curing and adjust heat-press temperature, time, and pressure as needed; print a control strip to check results.

How does DTF transfer troubleshooting help with peeling after washing and other adhesion issues?

DTF transfer troubleshooting emphasizes adhesion and durability. Pre-wash test fabrics, clean and dry surfaces, apply the recommended pressure and temperature, and consider higher-quality powder or different adhesive if needed; provide customers with proper wash guidelines to improve longevity.

How does DTF ink troubleshooting help keep colors consistent across runs?

DTF ink troubleshooting covers nozzle checks, cleaning routines, using quality inks designed for DTF, and color calibration across channels. Store inks properly and ensure printer temperatures and pressure settings align with the ink and film to prevent clogging, color drift, and uneven saturation.

Do different fabrics require different heat press settings in DTF transfer troubleshooting?

Yes. Fabric type affects temperature, time, and pressure. Always test on fabrics with similar properties, start from recommended ranges (for example 300–330°F / 150–165°C, 12–20 seconds), and adjust gradually. Use pre-press and even pressure to prevent shifting and ensure reliable results.

| Topic | Key Points |

|---|---|

| Overview | DTF transfer troubleshooting is a practical guide designed to help printers, crafters, and small businesses achieve reliable results with Direct-to-Film transfers. Most issues can be diagnosed and fixed with a systematic approach, reducing wasted prints, shortening turnaround times, and increasing customer satisfaction. |

| Categories of issues |

|

| Troubleshooting workflow (6 steps) |

|

| Common issues & fixes (selected) |

|

| DTF ink troubleshooting |

|

| Preventive maintenance & best practices |

|

| Advanced tips to optimize DTF transfer outcomes |

|

| Frequently asked questions about DTF transfer troubleshooting |

|

Summary

DTF transfer troubleshooting is the foundation of a repeatable, data-driven process that printers, crafters, and small businesses can apply to every project. By starting with solid file preparation, calibrating your printer, ensuring proper powder application, and using the right heat press parameters for your fabric, you’ll greatly reduce common DTF transfer issues. A methodical testing mindset and careful attention to adhesive behavior, film quality, and ink stability lead to durable finishes that stand up to washing and wear. Adopting preventive maintenance, standard operating procedures, and thorough documentation helps you scale production while maintaining consistency and customer satisfaction.