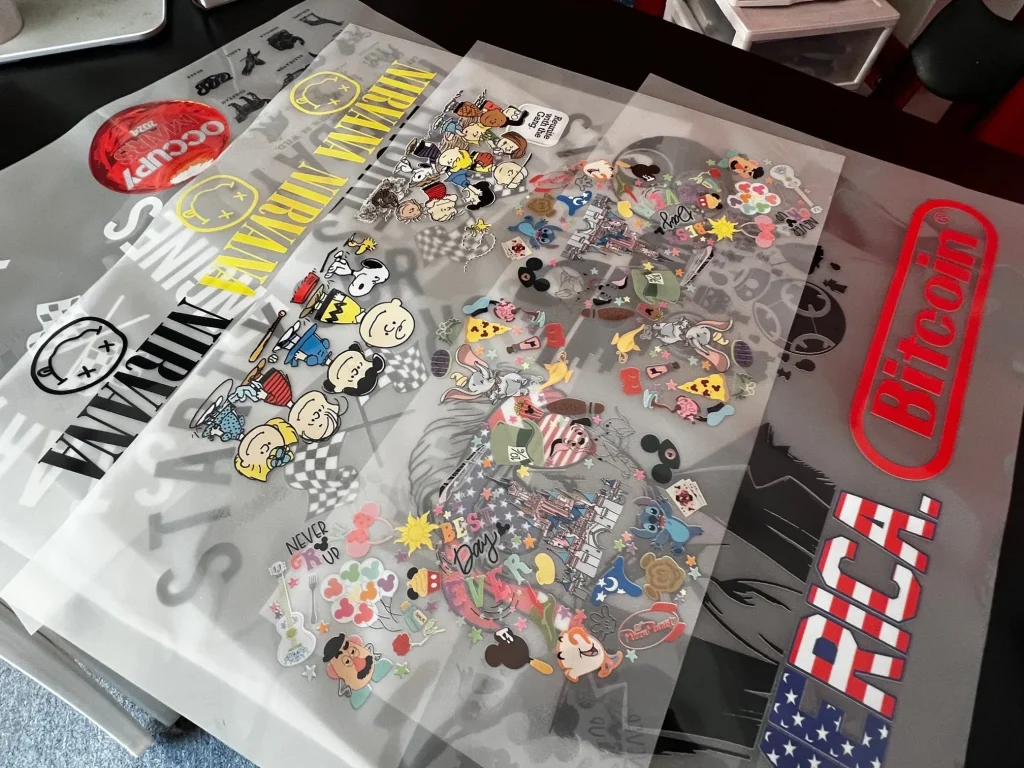

DTF gangsheets are a game-changer in the realm of Direct-to-Film printing, offering a groundbreaking solution for garment decorators seeking efficiency and quality. These innovative sheets allow multiple designs to be printed simultaneously on a single film, maximizing output while minimizing waste. In this comprehensive guide, we’ll delve into the intricate process of designing DTF gangsheets, providing essential DTF printing tips to help elevate your printing projects. By understanding the nuances of creating gang sheets, you can streamline your operations and boost your printing efficiency. Join us as we explore best practices, common pitfalls to avoid, and the transformative potential of DTF gangsheets in your printing endeavors.

In the world of fabric decoration, the term “gang sheets” often refers to a technique where various graphics are grouped together on a single printing surface. This method not only enhances productivity but also allows for an impressive variety of designs to be executed efficiently. Known for its flexibility, the Direct-to-Film (DTF) printing process, combined with strategic gang sheet design, can lead to significant cost savings and improved turnaround times. By optimizing how designs are arranged and printed, businesses can achieve exceptional quality with vibrant, durable colors that endure wash after wash. This guide will shine a light on the key strategies and considerations for mastering the art of creating effective gang sheets in your printing workflow.

Understanding the Basics of DTF Printing

Direct-to-film (DTF) printing has rapidly gained momentum in the garment industry for its efficiency and quality. At its core, DTF utilizes special films to transfer vibrant images directly onto fabrics. This technique not only provides stunning results but also allows for bulk printing, a crucial factor for businesses looking to increase their output without compromising on quality. Understanding the basics is essential for anyone looking to utilize DTF printing as it lays the foundation for creating impactful and effective designs.

The DTF printing process involves several steps, including printing on a special film, applying adhesive, and transferring the design onto the fabric using heat. It is vital for printers to familiarize themselves with the specific requirements needed for a successful print, such as the right temperature and pressure settings. By mastering these fundamentals, you will position yourself better in the market, ready to meet diverse customer demands with high-quality output.

Importance of DTF Gangsheets in Printing

DTF gangsheets are not just a convenience; they are a game-changer for printing efficiency. By allowing multiple designs to be printed simultaneously, gangsheets help reduce both material wastage and labor costs. This tactical approach is especially beneficial for small businesses or start-ups looking to maximize their resources while maintaining a high standard of output. Utilizing DTF gangsheets efficiently means faster turnaround times for orders, which can significantly enhance customer satisfaction.

Moreover, DTF gangsheets accommodate a range of design options, allowing businesses to offer more customizable products. With the ability to print several graphics on one sheet, printers can provide unique solutions that stand out in a competitive market. Not only does this elevate the printing process, but it also encourages creativity among designers, as they can explore varied concepts without the fear of overshooting their budget.

Optimizing workflows through the use of DTF gangsheets enables businesses to fulfill larger orders while keeping costs down, leading to increased revenue potentials. Companies that adopt this practice often find that they can scale their operations more effectively, making the transition into higher volume productions smoother and more manageable.

Best Practices for Designing DTF Gangsheets

When designing DTF gangsheets, it is crucial to embrace best practices that ensure both functionality and aesthetic appeal. An important first step is to size your designs appropriately, granting adequate spacing between each graphic for easy application. Understanding the dimensions of the film and the limitations of your printer will prevent overcrowding and allow for a seamless transfer process, ultimately leading to enhanced productivity.

Additionally, leveraging the right graphic design tools can greatly improve the DTF gangsheets process. Programs like Adobe Illustrator enable designers to create high-resolution artworks that are ideal for printing. By working in CMYK color mode and exporting designs at a minimum of 300 DPI, you can guarantee that your prints will come out vibrant and true to your original vision. Ensuring that every design adheres to these specifications can prevent costly mistakes during the final production.

Avoiding Common Mistakes in DTF Printing

As with any printing method, there are common pitfalls when it comes to DTF gangsheets that can be easily avoided with the right foresight. One major mistake is overcrowding the gangsheet, which can lead to difficulties during the cutting process and negatively impact design quality. It is essential to maintain a balanced layout that allows for both visual appeal and operational efficiency.

Another common error lies in neglecting to test designs prior to the final print run. Failing to conduct a test print can result in issues related to alignment, color discrepancies, or heat settings that may not suit the chosen fabric. By dedicating time to run preliminary tests, you can address any challenges in advance, which ultimately saves both time and resources in the long run. Regularly revisiting these practices will enhance your overall DTF printing experience, ensuring reliable outcomes with each project.

DTF Printing Tips for Optimal Results

Achieving optimal results in DTF printing involves implementing specific tips that can enhance the quality of your designs. Firstly, it is critical to source high-quality inks and films, as poor materials can compromise the integrity of the final product. Always choose reputable suppliers to ensure consistency in color vibrancy and adherence quality, as these are key elements that define successful DTF prints.

Additionally, regular maintenance of your printing equipment cannot be overlooked. Keeping print heads clean and ensuring that all machinery is functioning correctly is essential for preventing defects and prolonging the lifespan of your equipment. Implementing preventive maintenance routines will create a stable production environment, allowing for greater efficiency and minimal disruptions.

Leveraging Technology for DTF Gangsheets Creation

Advancements in technology have streamlined the process of creating DTF gangsheets, offering printers effectively designed online tools that ensure accuracy and compliance with printing requirements. Utilizing these online gangsheets builders can greatly enhance the efficiency and ease of designing, allowing users to focus on creativity rather than technical detailing. Furthermore, these tools often provide templates that cater to various fabric types and printing settings, making it easier for both novices and experienced users alike.

Incorporating technology into the DTF printing process not only saves time but can also improve the standardization of designs across orders. As the industry continues to evolve, staying updated on the latest software and design tools will ensure that your DTF printing practices remain competitive. Embracing technology can help you achieve consistent quality, allowing for the successful execution of more intricate designs in your gangsheets.

Frequently Asked Questions

What are DTF Gangsheets and how do they improve printing efficiency?

DTF gangsheets are sheets of film designed to hold multiple designs for Direct-to-Film (DTF) printing. By allowing multiple images to be printed in a single run, DTF gangsheets greatly improve printing efficiency, reduce material waste, and save time during the production process. This approach is particularly advantageous for garment printers, as it maximizes output while maintaining high-quality results.

What are the key tips for designing DTF gangsheets effectively?

When designing DTF gangsheets, consider the total size of your transfers and leave adequate space between designs for cutting. Use graphic design software like Adobe Illustrator or CorelDRAW for compatibility with DTF specifications, and ensure designs are high-resolution (300 DPI) for optimal print quality. Following heat press instructions closely is also essential to achieve the best results.

How can I avoid common mistakes when creating DTF gangsheets?

To avoid common mistakes when creating DTF gangsheets, ensure not to overcrowd the sheet, as this can lead to cutting errors. Always check fabric compatibility with the film you’re using, and conduct test prints to identify any potential issues with design placement or color fidelity. These steps help in achieving better final prints.

What materials are necessary for successful DTF printing using gangsheets?

Successful DTF printing using gangsheets requires high-quality films, inks, and transfer materials. Sourcing your materials from reputable suppliers is essential to guarantee consistency in your prints and enhance the overall quality of your garments. Regular maintenance of your printing equipment is also crucial for achieving reliable results.

Can you provide DTF printing tips for maximizing the utility of gangsheets?

To maximize the utility of DTF gangsheets, invest in quality materials, maintain your printing equipment regularly, and utilize online gangsheets builders to streamline the design process. Keeping up with industry trends will also improve your DTF printing practices, enabling you to produce high-quality prints efficiently.

What is the importance of test printing when working with DTF gangsheets?

Test printing is a crucial step when working with DTF gangsheets as it allows you to identify and resolve issues related to design placement, color fidelity, and heat settings before the final print run. This practice minimizes material waste and ensures that your final prints meet expectations, thereby enhancing overall print quality.

| Key Feature | Description |

|---|---|

| Efficiency | Allows multiple designs to be printed simultaneously, saving time and labor. |

| Cost-Effectiveness | Utilizes a single sheet for multiple designs, reducing waste and material costs. |

| Versatility | Compatible with various fabrics like cotton and polyester, suitable for diverse projects. |

| Quality | Produces vibrant and durable prints, enhancing the longevity of designs. |

| Design Consideration | Maintain appropriate spacing, use compatible design tools, and optimize for quality. |

| Common Mistakes | Avoid overcrowding sheets, test prints, and ensure fabric compatibility. |

| Best Practices | Invest in quality materials, maintain equipment, and stay updated on industry trends. |

Summary

DTF Gangsheets are a transformative solution in the garment printing industry, enabling users to harness the efficiency of printing multiple designs on a single sheet. This guide elucidates the advantages of using DTF gangsheets, particularly their inherent qualities of cost-effectiveness, versatility, and print durability. By adhering to best practices in design and application while being mindful of common mistakes, users can maximize their printing potential. Ultimately, mastering DTF gangsheets can significantly enhance productivity and the quality of printed garments, making it an essential skill for anyone in this field.