The DTF Gangsheet Builder revolutionizes the way custom designs are created, seamlessly merging art and technology. With DTF (Direct-to-Film) printing, this innovative tool enhances the printing workflow by allowing designers to efficiently produce high-quality prints on various fabrics. Whether you’re crafting personalized tees or unique tote bags, the convenience of gangsheet printing ensures vibrant results without sacrificing time or resources. Embracing this cutting-edge method opens up endless possibilities for fabric printing, helping businesses stand out in a competitive market. Unlock your creative potential with the DTF Gangsheet Builder and watch your custom designs come to life!

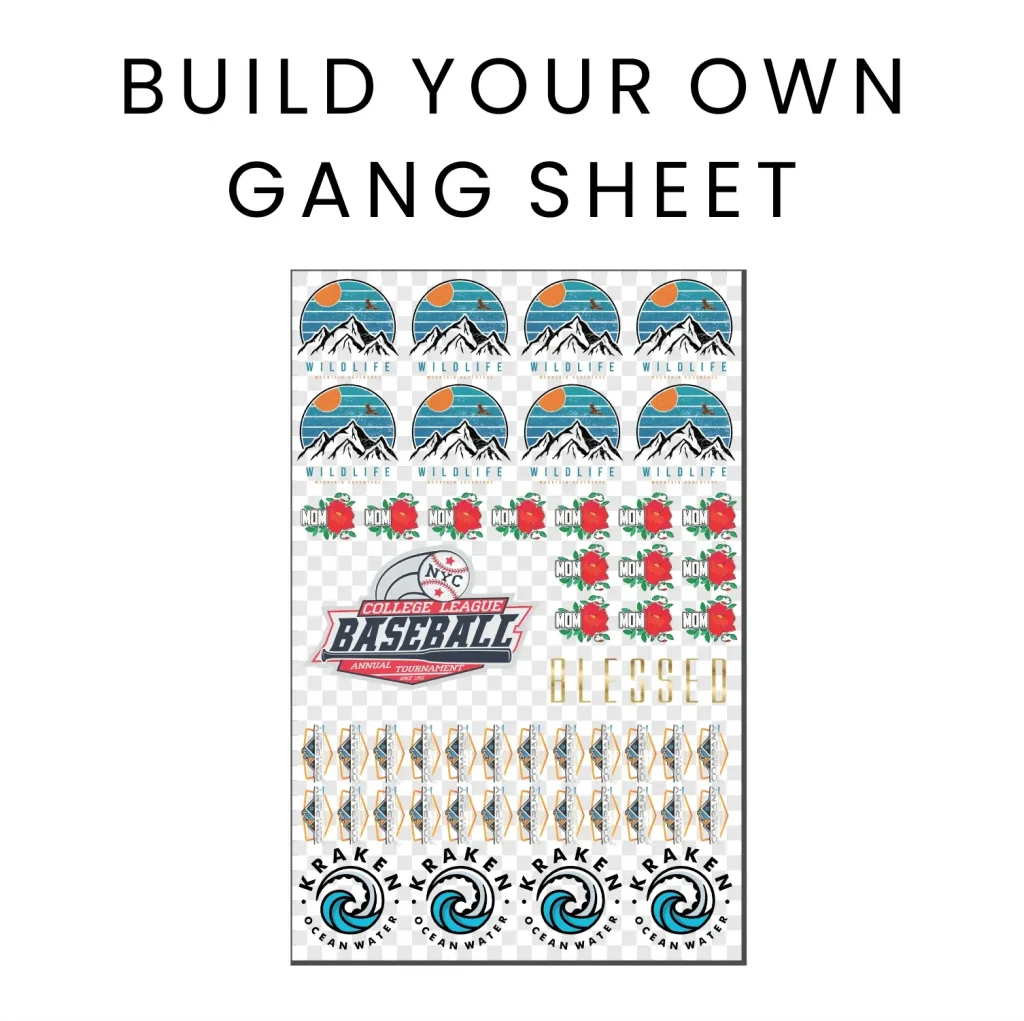

Introducing the DTF Gangsheet Builder, a game-changer for fabric design enthusiasts looking to streamline their printing processes. This tool leverages advanced direct-to-film (DTF) technology, enabling creators to assemble multiple designs onto one sheet with remarkable precision. As a result, gangsheet printing not only maximizes material usage but also allows for the production of stunning, vibrant graphics suitable for a wide array of fabric types. From personalized apparel to bespoke accessories, this versatile printing solution accelerates the creation of custom designs while enhancing overall efficiency. By harnessing its capabilities, designers can navigate the complexities of the printing workflow with ease.

Exploring the Benefits of DTF Gangsheet Printing

DTF gangsheet printing offers an array of benefits, setting it apart from conventional printing methods. One of its prime advantages is its ability to print multiple designs onto a single sheet, which significantly optimizes material usage. This not only reduces waste but also streamlines the production process, making it ideal for businesses looking to increase efficiency. Additionally, DTF printing’s compatibility with various fabric types, including cotton and polyester, allows for a diverse range of applications, from clothing to promotional items.

Moreover, the vibrant color reproduction and detail retention that DTF gangsheet printing provides make it a frontrunner for custom designs. This method uses advanced ink technology to ensure that colors remain bold and consistent over time, even after multiple washes. As a result, designers and entrepreneurs can confidently offer high-quality products that meet client expectations and stand out in a competitive market.

The Step-by-Step Process of Creating DTF Gang Sheets

Creating DTF gang sheets begins with designing your artwork using graphic software, where precision and creativity blend to produce captivating visuals. Programs like Adobe Illustrator are preferred due to their robust features, allowing for the design of intricate patterns that can be scaled and adjusted to fit various products seamlessly. It’s vital to ensure that the resolution is high enough to capture detailed graphics, as this directly impacts the final output quality.

Once the designs are finalized, the next step involves setting up the gang sheet layout. Optimal spacing between designs is crucial to avoid overlap and ensure clean prints. Using layout optimization tools can help enhance the arrangement on the gang sheet, thereby increasing productivity during the printing phase. After this preparation, printing can proceed using a specialized DTF printer, while adhering to the specific settings designed for DTF workflows, ensuring color accuracy and detail retention.

Maximizing Efficiency in DTF Printing

Efficiency in DTF printing can be significantly enhanced with a few strategic practices. For example, designing for batch printing is an excellent way to optimize the production workflow. By creating several designs that align seamlessly on a gang sheet, printers can minimize their setup times and increase output volume. Implementing a batch processing method also helps in reducing operational interruptions, which is essential for maintaining a steady production pace.

Furthermore, using a consistent color palette across all designs not only fosters brand recognition but also simplifies the management of colors throughout the printing process. This approach ensures that any future prints maintain the same high-standard quality, while also streamlining the task of matching colors during production. Such techniques contribute significantly to achieving greater productivity and minimizing costs in the DTF printing workflow.

Essential Equipment for DTF Printing Success

To embark on a successful DTF printing venture, having the right equipment is pivotal. A dedicated DTF printer is essential, as it employs unique ink formulas specifically designed for transferring onto films. This type of printer produces vibrant, durable outputs that can withstand rigorous use, making it a worthwhile investment for businesses aiming to produce high-quality prints.

In addition to a DTF printer, the selection of special films compatible with DTF inks is crucial. These films serve as the medium for carrying the printed designs to the fabric. Similarly, a robust heat press is needed to ensure that the heat and pressure applied during the transfer process are consistent and effective. The synergy among these tools enhances the overall productivity and quality of the DTF printing process.

Design Tips for Stunning DTF Gang Sheets

Designing effective DTF gang sheets requires a finesse that combines artistry with technical precision. Start by ensuring your images are high-resolution to avoid pixelation when scaling. Additionally, leveraging color theory can enhance the visual appeal of your designs, making them more attractive to potential customers. Consider contrasting colors or cohesive themes that resonate with your target audience, as this can significantly impact sales.

Moreover, experimenting with various layouts can lead to discovering the most optimal arrangement for your gang sheets. Tools that allow you to preview the print before executing it can be incredibly helpful in visualizing how your designs will look once printed. This kind of foresight can save a lot of time and materials, contributing to overall efficiency in your printing process.

The Future of DTF Printing with Gang Sheet Builders

The future of DTF printing appears bright, especially with the advancements in gang sheet builder technologies. These innovations facilitate creating intricate designs more easily and with heightened precision, paving the way for greater creative exploration in the printing landscape. As these tools continue to evolve, they are set to redefine industry standards, making high-quality, custom fabric prints accessible to businesses of all sizes.

Furthermore, the growing popularity of personalized and custom products in multiple markets means that the demand for efficient DTF printing solutions will only increase. As more entrepreneurs and small businesses realize the potential of DTF gang sheets, we can expect a surge in creative collaborations and unique design offerings. Staying ahead by embracing the latest technologies and methodologies will be critical for competitors in this dynamic field.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it work?

A DTF Gangsheet Builder is a tool that allows users to create custom designs using DTF (Direct-to-Film) printing technology. It enables the efficient arrangement of multiple design elements onto a single film sheet, which is then printed and transferred onto fabrics. This process simplifies production and helps to reduce material costs while producing vibrant, high-quality prints.

Why is DTF printing preferred for custom designs?

DTF printing is often preferred for custom designs because it offers versatility across various fabrics, including cotton and polyester. This method produces vivid colors and intricate details that stand out. Using a DTF Gangsheet Builder also maximizes efficiency by allowing multiple designs to be printed simultaneously, saving time and reducing costs.

What equipment is necessary for using a DTF Gangsheet Builder?

To utilize a DTF Gangsheet Builder effectively, you will need essential equipment including a DTF printer, special DTF film compatible with the inks, and a heat press for transferring the designs to fabric. This combination ensures that the vibrant colors and detailed artwork are accurately reproduced in the final fabric printing.

How can I create my first DTF gang sheet using a DTF Gangsheet Builder?

Creating your first DTF gang sheet involves designing your artwork in software, setting up the gang sheet with proper spacing, printing it on DTF film, and then transferring the design onto your chosen fabric using a heat press. Follow step-by-step guides for optimized layout and printer settings to achieve the best results.

What are the benefits of using gangsheet printing in DTF projects?

Gangsheet printing in DTF projects offers several benefits, including reduced material waste by printing multiple designs on one sheet, enhanced production efficiency through batch printing, and significant cost savings. It also frees up creative possibilities for designers to explore diverse custom designs in a streamlined manner.

What tips can help maximize production efficiency with DTF gang sheets?

To maximize production efficiency with DTF gang sheets, consider designing multiple prints to utilize space effectively, organize prints into batches for streamlined workflow, and maintain a consistent color palette for easier management of designs. These strategies help reduce time and effort while ensuring high-quality outputs.

| Key Point | Details |

|---|---|

| DTF Gangsheet Builder | A technology that allows for efficient production of vibrant prints on various fabrics. |

| How DTF Works | Prints designs on a special film that is then applied to fabric with heat and pressure. |

| Advantages of DTF Printing | 1. Versatility with various materials. 2. Vivid colors and details. 3. Cost efficiency through gang sheets. |

| Essential Tools | 1. DTF Printer 2. Special Film 3. Heat Press |

| Steps to Create DTF Gang Sheet | 1. Design Artwork. 2. Set Up Gang Sheet. 3. Print it. 4. Transfer to Fabric. |

| Production Efficiency Tips | 1. Design for multiple prints. 2. Batch printing. 3. Maintain a consistent color palette. |

Summary

The DTF Gangsheet Builder revolutionizes the way designers and printers create stunning custom designs by enabling the production of vibrant and durable prints suitable for a variety of fabrics. This remarkable technology simplifies the printing process through its unique method of applying designs, enhancing workflow efficiency, and maximizing cost-effectiveness. With essential tools, clear steps to create gang sheets, and efficiency tips in mind, users can unleash their creativity while ensuring high-quality results. Whether you are a seasoned professional or a newcomer to printing, the DTF Gangsheet Builder is your gateway to exploring endless design possibilities!