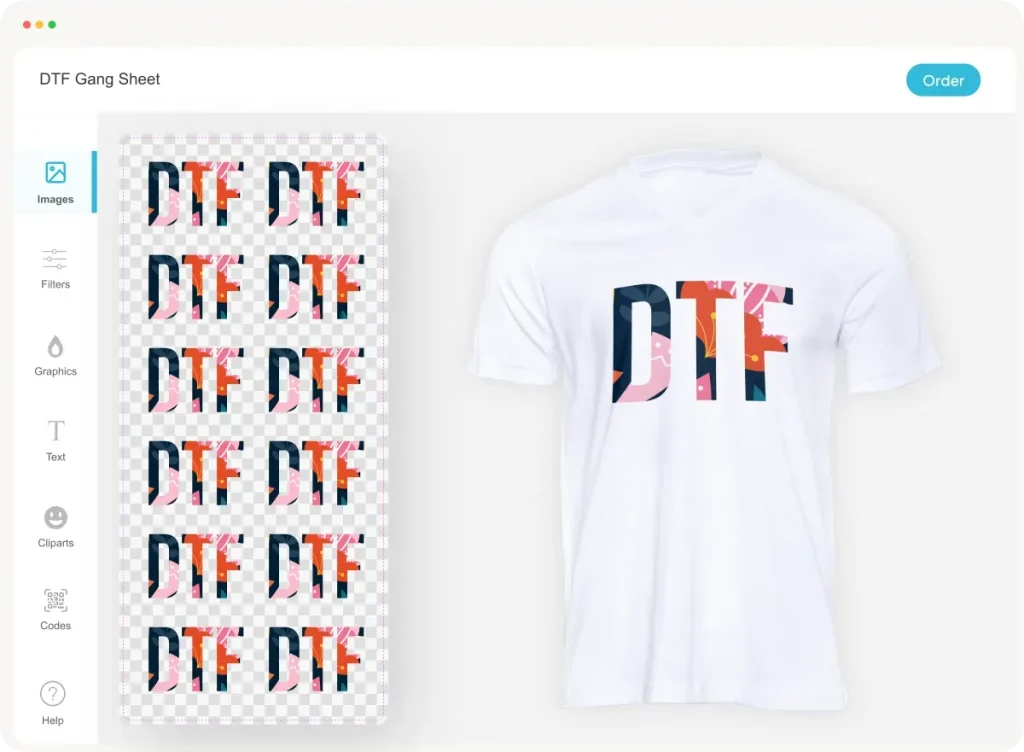

In the world of Direct-to-Film (DTF) printing, the DTF gangsheet builder stands out as a revolutionary tool that maximizes efficiency and quality by allowing the simultaneous printing of multiple designs on a single sheet. This innovative method has transformed how designers and print shops create vibrant graphics, but it’s essential to understand its nuances to avoid common pitfalls. As we delve into the complexities of using a DTF gangsheet builder, we will uncover five prevalent mistakes that can compromise your printing projects. Proper design preparation, color management, regular machine maintenance, loading strategies, and prepress checks are all vital components that impact the final output. By being aware of these factors, you can harness the full potential of DTF printing and achieve stunning results for your garments and other print applications.

Exploring the realm of printing, the method of gangsheet creation in DTF printing presents a solution for efficiently producing high-quality designs. This approach enables users to streamline their printing process by combining various images onto a single film, significantly reducing waste and time. However, just like any advanced printing technique, it is accompanied by its own set of challenges that can hinder the production if not addressed properly. Understanding design essentials, ensuring precise color accuracy, and maintaining printer integrity are crucial for optimal outcomes. In this article, we will examine the critical aspects to enhance your experience with gangsheet builders in DTF printing.

Inadequate Design Preparation for DTF Printing

When utilizing a DTF gangsheet builder, proper design preparation is crucial for achieving optimal results. Designs must be high-resolution, ideally at a minimum of 300 DPI, to ensure clarity and vibrance in printed materials. Additionally, converting your colors from RGB to CMYK is essential. This conversion aligns the digital representation of colors to those that will be printed, preventing unexpected differences that can occur due to varying color processes. Users often overlook these details, leading to disappointment when the printed product does not match their expectations.

A thorough understanding of the specifications required by your DTF printer is also a vital aspect of design preparation. Familiarize yourself with acceptable file formats, dimensions, and any specific resolution requirements for your equipment. By adhering to these guidelines, you significantly reduce the risk of common printing errors, such as misalignment or pixelation, allowing for a smoother printing process and higher quality outputs. Investing time in preparation can save you from costly mistakes later in the printing cycle.

Effective Color Management in DTF Printing

Neglecting color management is a frequent mistake among DTF printing users, leading to unsatisfactory results that might not reflect the intended design. To achieve accurate color reproduction, it’s crucial to establish proper calibration processes for both your monitor and printer. Regular calibration ensures that the colors you see on your screen will closely match the final print. Tests using the same media and printer settings as your final outputs allow you to preemptively identify color discrepancies that could arise during bulk production.

Further, adjusting the color profile settings in your design software to align with your printer’s specifications can greatly enhance color fidelity. Always conduct test prints to verify that colors appear as expected, and make adjustments as necessary. This practice not only improves the overall quality of the prints but also instills confidence in clients regarding color accuracy, ultimately boosting customer satisfaction and reducing waste associated with misprints.

The Importance of DTF Machine Maintenance

Regular machine maintenance is paramount in sustaining the longevity and performance of your DTF printer. Neglecting these essential upkeep practices, such as cleaning the printhead and ensuring appropriate storage of inks, can result in issues like clogged nozzles and inconsistent print quality. Establishing a routine maintenance schedule – including daily, weekly, and monthly tasks – forms a solid foundation for maintaining your equipment, thereby minimizing unexpected downtimes and costly repair bills.

In addition to routine cleaning, be proactive about addressing any signs of wear or malfunction. Keeping the printing environment clean and free from dust or debris that might obstruct the printing process is vital for optimal performance. By prioritizing machine maintenance, you set the stage for consistent print quality, reliability, and efficiency, which are crucial for fulfilling customer demands and meeting production deadlines.

Avoiding Overloading the Gangsheet

When working with a DTF gangsheet builder, it might be tempting to load the sheet with as many designs as possible to maximize efficiency. However, overloading can lead to a range of issues, including poor adhesion and transfer quality. It’s essential to find a balance between maximizing space and allowing adequate room between designs to facilitate a smooth transfer process. Overcrowding the gangsheet may result in distorted designs or incomplete transfers, negatively impacting the final results.

Planning is paramount when it comes to arranging designs on the gangsheet. Analyze spacing requirements for each print and ensure that there’s enough room for precision during the transfer phase. Consider taking time to create mock layouts prior to the final print run, allowing you to visualize and adjust the arrangement for optimal handling and quality. This strategic approach not only enhances the efficiency of the process but also improves the final product—satisfying both your operational standards and client expectations.

Conducting Comprehensive Prepress Checks

Skipping prepress checks is a common mistake that can lead to significant issues down the line. Before sending your designs to the DTF gangsheet builder, conduct a thorough review to confirm dimensions, orientation, and bleed areas. This final step can prevent misprints and ensure your designs adhere to the intended specifications, ultimately saving you time and resources. A diligent prepress process guarantees that your prints meet quality expectations and reduces the risk of costly reprints.

A robust prepress checklist should focus on several key aspects. Verify that the correct dimensions match the intended print size, check for orientation issues that could lead to flipping problems, and ensure bleed areas are set appropriately to avoid cropping important elements of your design. These simple yet effective practices can significantly improve the overall print quality and output consistency, ultimately enhancing customer satisfaction when utilizing your DTF printing services.

Common DTF Printing Mistakes and How to Avoid Them

Understanding the prevalent mistakes in DTF printing can arm you with the knowledge necessary to avoid them. Beyond inadequate design preparation, common errors include neglecting proper color management and failing to maintain DTF machines. Each of these mistakes can undermined final product quality and create inefficiencies in your workflow. By actively addressing these areas and implementing best practices, you can consistently enhance the quality of your prints.

Additionally, staying informed about the latest DTF printing tips and resources is essential for success. Engaging with the DTF community, participating in webinars, and accessing online tutorials can provide valuable insights that refine your skills and techniques. This continuous learning will not only help prevent mistakes but can also inspire new creative approaches, enabling you to fully leverage the capabilities of your DTF gangsheet builder.

Frequently Asked Questions

What are the key design preparation tips for using a DTF gangsheet builder?

When using a DTF gangsheet builder, it’s crucial to ensure that your designs are prepared meticulously. Aim for high-resolution graphics of at least 300 DPI and convert colors to the CMYK color model for accurate color representation. Familiarizing yourself with your DTF printer’s specific requirements for file formats and dimensions will help avoid common alignment and print quality issues.

How can I avoid common DTF printing mistakes when using a gangsheet builder?

To avoid common DTF printing mistakes when using a gangsheet builder, focus on proper design preparation, effective color management, and machine maintenance. Regularly calibrate your printer, conduct test prints before bulk production, and ensure your designs don’t overload the gangsheet to maintain quality and efficiency.

What should I consider for effective color management in DTF printing?

For effective color management in DTF printing, regularly calibrate your monitor and printer, and conduct test prints on the same media as your final output. Adjust the color profile settings in your design software to match your printer’s specifications, ensuring vibrant and accurate colors in your DTF gangsheet printing.

What are the best practices for DTF machine maintenance?

To maintain your DTF printer, establish a regular cleaning schedule for the printhead and perform maintenance checks. Properly store inks to prevent drying and keep your printing area clean to avoid dust interference. These practices are essential for ensuring high print quality and maximum uptime with your DTF gangsheet builder.

How do I effectively space designs on a DTF gangsheet?

When using a DTF gangsheet builder, avoid overcrowding by analyzing the spacing requirements for each design. Make sure there’s enough room between designs for proper transfer and that each design is appropriately sized on the sheet. Conducting mock layouts can help you find the best arrangement and maintain print quality.

What is a prepress check and why is it important for DTF printing?

A prepress check involves reviewing all designs before printing, ensuring correct dimensions, orientation, and bleed areas. This final review process is crucial in DTF printing to avoid costly mistakes and ensure that your designs meet the intended specifications, ultimately saving time and resources in the production stage.

| Mistake | Description | Tips to Avoid |

|---|---|---|

| 1. Inadequate Design Preparation | Poor design setup can cause alignment issues and affect print quality. | – Use high-resolution graphics (300 DPI minimum). – Convert colors to CMYK. |

| 2. Neglecting Proper Color Management | Improper color calibration can lead to unexpected hues in prints. | – Regularly calibrate monitor and printer. – Test prints for color accuracy. |

| 3. Ignoring Machine Maintenance | Poor maintenance leads to clogging and inconsistent print quality. | – Schedule regular cleanings and checks. – Store inks properly. |

| 4. Overloading the Gangsheet | Overcrowding can cause transfer difficulties and poor adhesion. | – Ensure adequate spacing for each design. – Conduct mock layouts before finalizing. |

| 5. Skipping Prepress Checks | Neglecting final checks can result in costly print errors. | – Verify dimensions and orientation. – Confirm bleed areas are set correctly. |

Summary

The DTF gangsheet builder can be a remarkable tool in your printing arsenal, but recognizing and avoiding common pitfalls is crucial for maximizing its potential. By taking the time to prepare your designs adequately, manage colors effectively, maintain your machine diligently, avoid overcrowding, and perform thorough prepress checks, you will ensure superior print quality and efficiency in your projects. This attention to detail not only enhances your workflow but also contributes significantly to customer satisfaction, allowing your business to thrive in the competitive landscape of DTF printing.