The DTF Gangsheet Builder is an innovative tool designed specifically for enhancing the Direct to Film (DTF) printing process. This powerful software allows graphic designers and print businesses to maximize efficiency by organizing multiple designs onto a single film sheet. As DTF printing continues to revolutionize the textile industry, mastering gangsheet design becomes indispensable for anyone looking to succeed in custom fabric printing. By utilizing the DTF Gangsheet Builder, users can optimize gangsheet layouts to minimize waste and reduce production costs significantly. Whether you’re a seasoned professional or just starting, this guide will provide you with the essential tips and resources to navigate the complexities of DTF printing successfully.

In the realm of modern printing technology, the concept of a gangsheet design is a game changer for artists and business owners alike. Known for its efficiency, the gangsheet technique permits the simultaneous printing of numerous images on a single film, streamlining the workflow in DTF printing. This method not only conserves materials but also ensures that the transfer process is both quick and cost-effective. As the popularity of DTF software grows, so does the need for comprehensive guidance on how to optimize gangsheet layouts for maximum impact. Embracing these innovative tools and methods will allow you to elevate your printing projects to new heights.

Understanding DTF Printing and Its Applications

Direct to Film (DTF) printing represents a significant advancement in the textile printing industry. This innovative technique allows for vibrant and detailed prints that adhere seamlessly to a diverse range of materials. DTF printing works by applying specialized inks onto a film, which are then transferred onto garments using heat and pressure. This method caters to a wide variety of fabrics, making it a preferred choice for custom apparel, promotional items, and more.

As the demand for personalized clothing grows, understanding DTF printing’s applications becomes crucial. From creating intricate designs for fashion brands to producing custom merchandise for events, DTF printing enables creativity without limits. The gangsheet methodology further enhances this process, allowing multiple designs to be printed simultaneously, which not only optimizes material use but also cuts down production times significantly.

Getting Started with DTF Gangsheet Builder

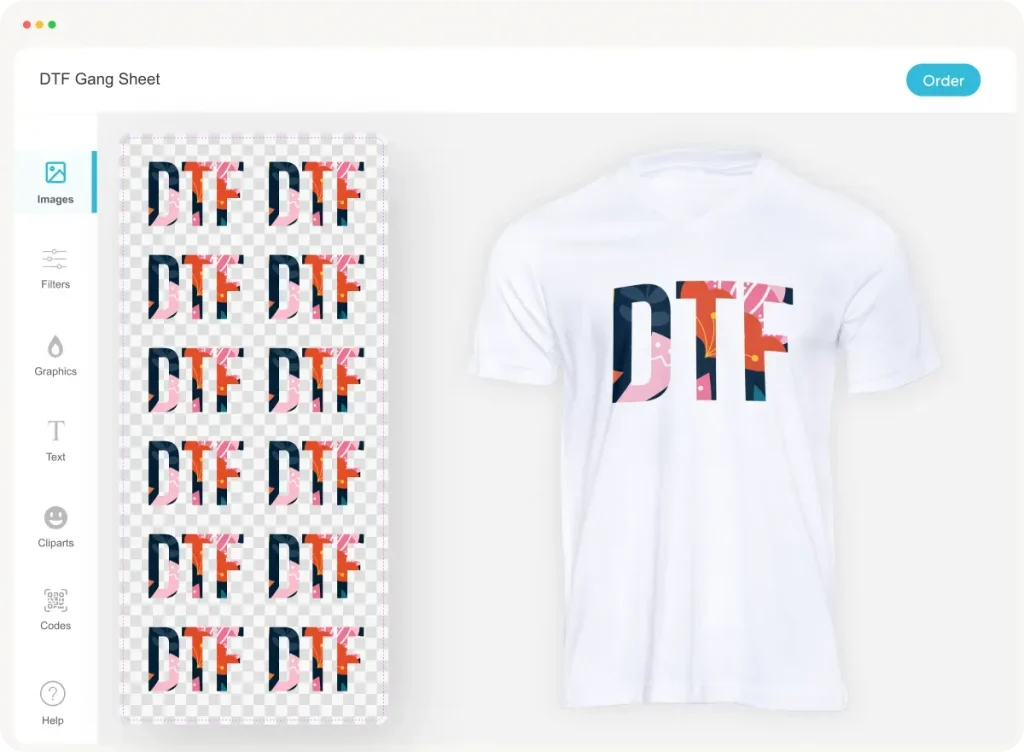

To embark on your journey with the DTF Gangsheet Builder, it is essential to start with the right software. Programs specifically designed for DTF printing streamline the process of creating gang sheets by providing necessary tools for layout and design. These specialized DTF software solutions can dramatically simplify your workflow and ensure that your designs maintain high quality throughout the printing procedure.

Familiarization with the software interface is crucial for success. The DTF Gangsheet Builder typically includes features that allow users to easily manipulate image sizes, alignments, and spacing to create optimal layouts. Understanding these functionalities not only helps in generating visually appealing designs but also ensures that you make the best use of the printing area, thereby saving time and reducing material waste.

Image Optimization Techniques for DTF Printing

Image optimization is a key aspect of DTF printing that directly impacts print quality. High-resolution images are essential to maintain clarity and detail in your designs. It is advisable to convert your images to CMYK color mode, as this color profile is ideal for printing and helps in achieving accurate color representation. Furthermore, using vector graphics can also yield superior results, as they can be resized without losing image quality.

Before placing your designs onto a gangsheet, ensure all images are correctly optimized, including adjusting DPI settings and checking color profiles. These practices not only enhance visual effects on the final product but also mitigate issues related to blurriness or pixelation that can occur if images are not appropriately prepared.

Efficient Layout Design for Gangsheet Production

Creating an efficient layout is integral to maximizing the potential of your DTF gangsheet. Utilizing software templates can simplify this process by providing standard sizes and predefined spacing, which promotes consistency and enhances overall workflow. Aim to minimize gaps between images on the gangsheet, allowing you to fit more designs, which reduces material waste while increasing profitability.

When designing layouts, think strategically about how each design interacts with others. Consider the shapes and sizes of images to create a balanced composition that maintains visual appeal. Additionally, keep in mind that arranging designs in a harmonious fashion can also streamline the printing process, allowing for faster production and easier handling.

Conducting Test Prints Before Full Production

Conducting test prints is a crucial step in the DTF printing process, as it helps identify any issues before embarking on a full production run. These test prints allow you to evaluate crucial settings such as ink density, coating application, and heat press parameters. By adjusting these variables based on your test results, you can significantly improve the quality of your final prints.

Moreover, running test prints contributes to better resource management. It not only conserves materials but also helps avoid costly errors that may arise from miscalculations. Engaging in this practice of thorough testing can save time and enhance your reputation by providing clients with top-notch products that exceed their expectations.

Best Practices for Finalizing DTF Prints

Finalizing your DTF prints is nearly as important as the initial printing process itself. Proper curing methods are essential to ensure durability and longevity of your designs. Neglecting to cure prints adequately can lead to smudges and fading, drastically diminishing the quality of your work. By following correct curing protocols, you ensure that your designs remain vivid and intact even after multiple washes.

Additionally, familiarize yourself with the types of films and inks you are using, as each may have different requirements for optimal curing. Implementing industry-best practices in finalizing prints not only reinforces the quality of your work but also builds trust with your clients, establishing you as a reliable provider in the DTF printing market.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance DTF printing?

The DTF Gangsheet Builder is a specialized software tool that allows users to create gang sheets for Direct to Film (DTF) printing. It enhances DTF printing by enabling the arrangement of multiple designs on a single sheet, which maximizes film usage, reduces waste, and cuts production costs.

How can I optimize my images for the DTF Gangsheet Builder?

To optimize your images for the DTF Gangsheet Builder, ensure they are high resolution and saved in CMYK color mode. Using vector images can also help maintain clarity when scaling. Additionally, minimize space between designs in your gangsheet layout to maximize print area.

What are the essential steps to create a successful gangsheet design using the DTF Gangsheet Builder?

Creating a successful gangsheet design with the DTF Gangsheet Builder involves setting up the software, optimizing images, designing the layout with minimal space between items, conducting test prints, and properly curing the prints to ensure quality.

Are there specific software options recommended for DTF gangsheet design?

Yes, popular software for DTF gangsheet design includes Adobe Illustrator and dedicated DTF software that supports layout creation and image optimization. These tools can streamline the process and enhance the quality of your final prints.

What common mistakes should I avoid when using the DTF Gangsheet Builder?

Common mistakes to avoid when using the DTF Gangsheet Builder include neglecting image optimization, overcrowding the gangsheet layout, skipping test prints, and improper curing post-printing. These errors can adversely affect print quality and efficiency.

Where can I find DTF printing guides to improve my knowledge on using the DTF Gangsheet Builder?

You can find comprehensive DTF printing guides from sources like SuperColor’s DTF Guide, YouTube tutorials from channels like T-Shirt Help Desk, and articles on design tips from Creative Fabrica that specifically address gangsheet design and DTF printing techniques.

| Key Area | Description |

|---|---|

| Introduction to DTF Printing | Direct to Film (DTF) printing allows vibrant images to transfer onto fabrics with a gangsheet builder, reducing costs and maximizing efficiency. |

| Key Resources | Resources include SuperColor’s DTF Guide, YouTube tutorials from Printavo and T-Shirt Help Desk, and design tips from Creative Fabrica to aid in mastering DTF techniques. |

| Essential Steps for Building a Gangsheet | 1. Software Setup 2. Image Optimization 3. Layout Design 4. Test Printing 5. Finalizing Prints |

| Additional Resources | Printavo Blog and online forums such as Print Planet provide further insights and best practices for DTF printing. |

Summary

DTF Gangsheet Builder is an indispensable tool for anyone looking to enhance their custom printing workflow. By mastering this innovative technology, creators can efficiently combine multiple designs onto one film sheet, maximizing both creativity and cost-effectiveness. Engaging with various resources, such as online tutorials, community forums, and expert blogs will not only deepen your understanding but also elevate your printing capabilities to new heights. As you explore the vibrant possibilities of DTF printing, you’ll find numerous opportunities to express your artistic vision and deliver high-quality results.