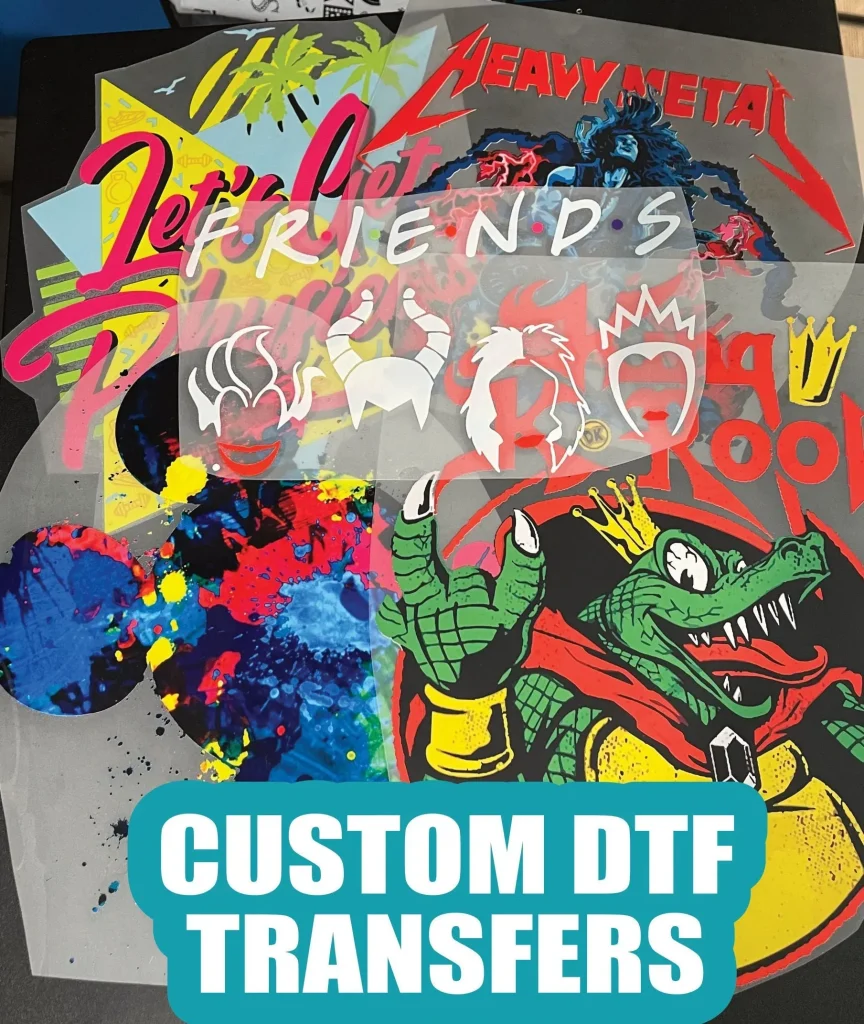

DTF transfers, or Direct-to-Film transfers, are transforming the landscape of custom t-shirt printing in extraordinary ways. This innovative printing method allows intricate designs to be transferred directly onto a variety of fabric types, making it one of the leading screen printing alternatives available today. As businesses and individuals alike seek more versatile and efficient ways to create personalized apparel, DTF printing stands out for its affordability and exceptional quality. In this blog post, we will delve into the world of DTF transfers, exploring how this modern technique enhances creativity and meets consumer demand in the custom apparel market. Join us as we uncover the numerous benefits and technological advancements that are propelling DTF printing into the spotlight.

Direct-to-Film transfers represent a groundbreaking approach to custom apparel decoration, particularly in the realm of t-shirt production. This technique involves applying designs printed on a specialized film onto fabrics with heat and pressure, offering a swift and cost-effective solution for those in search of personalized clothing. By eliminating traditional screen printing methods, businesses can produce high-quality, vibrant prints without the extensive setup time typically involved. Moreover, the adaptability of this printing method allows for compatibility with numerous fabric types, making it an attractive option for custom garment creators. In this discussion, we will explore how this state-of-the-art printing technology is reshaping the industry, meeting the growing consumer appetite for unique and personalized fashion.

The Evolution and Impact of DTF Printing

The evolution of Direct-to-Film (DTF) printing has brought about a remarkable transformation in the custom T-shirt printing landscape. This innovative technology has not only simplified the printing process but has also enhanced the quality of prints significantly. Unlike traditional printing methods, which often required extensive setup and time-consuming procedures, DTF printing allows for a quick turnaround. This shift has made DTF printing an appealing option for both small businesses and large enterprises looking to meet the growing demand for personalized apparel.

Moreover, the impact of DTF printing extends beyond just efficiency; it resonates with the increasing consumer desire for unique fashion statements. As customers seek to express their individual identities through custom designs, DTF printing emerges as a versatile solution. Its ability to offer high-quality prints across a variety of fabrics has set a new benchmark in customized clothing, making it a frontrunner among screen printing alternatives.

Frequently Asked Questions

What are DTF transfers in custom t-shirt printing?

DTF transfers, or Direct-to-Film transfers, are a modern method of custom t-shirt printing where designs are printed onto a special film and then transferred onto fabric using heat and pressure. This technique is known for its versatility and ability to work on various materials like cotton and polyester.

How do DTF transfers compare to traditional screen printing?

Unlike traditional screen printing, DTF transfers eliminate the need for screens, allowing for quicker production times and immediate access to custom designs. Additionally, DTF offers vibrant colors and high-quality results across diverse fabric types, making it a compelling alternative.

What are the benefits of using DTF printing for personalized apparel?

DTF printing provides several advantages for personalized apparel, including cost-effectiveness, the ability to produce complex designs with vibrant colors, and compatibility with a wide range of fabrics. This makes it ideal for both small businesses and individual customers seeking unique t-shirt designs.

Can DTF transfers be used on different fabric types?

Yes, DTF transfers are remarkably versatile and can be used on various fabric types, including 100% cotton, polyester, and blended materials. This versatility allows businesses to offer a diverse range of custom t-shirt options.

What technological advancements have improved DTF printing?

Recent technological advancements in DTF printing include the development of specialized DTF printers, high-quality inks, and innovative transfer films that enhance adhesion and detail in printed designs. These improvements contribute to the overall quality and efficiency of DTF transfers.

Is DTF printing a cost-effective solution for custom apparel businesses?

Yes, DTF printing is considered a cost-effective solution, particularly for small businesses or startups. Its ability to print high-quality designs on demand, even in small batches, helps minimize waste and reduces initial investment costs, making it accessible for entrepreneurs in the custom apparel market.

| Key Points | Description |

|---|---|

| DTF Printing | A method that prints designs onto a special film, transferred to fabric using heat and pressure. |

| Material Compatibility | Can adhere to various fabric types including cotton, polyester, and blends. |

| Quality and Vibrant Colors | Produces bright, long-lasting colors that maintain vibrancy after multiple washes. |

| Cost-Effectiveness | Ideal for small businesses, allowing on-demand production with less waste. |

| Technological Innovations | Advancements in inks and printers enhance quality and user experience. |

| Market Growth | Increasing demand for unique, personalized products boosts DTF market expansion. |

Summary

DTF transfers are revolutionizing the custom apparel industry by providing a method that marries exceptional quality with cost-effectiveness and versatility. This innovative printing technique allows users to create vibrant, detailed designs on a wide range of fabric types. The technological advancements behind DTF printing continue to elevate the capabilities of custom T-shirt production, catering to the growing demand for personalized clothing. As businesses embrace DTF technology, they not only enhance their product offerings but also adapt to modern consumer trends, positioning themselves for significant success in an evolving market.