DTF Transfers, an abbreviation for Direct-to-Film printing, is revolutionizing the custom apparel printing industry. This cutting-edge printing technology provides a distinct advantage by allowing designs to be printed on a specialized film and then transferred onto various fabrics, ensuring vibrant and high-quality outputs. As businesses chase innovative sustainable printing solutions, DTF transfers stand out due to their versatility and cost-effectiveness, making them perfect for apparel customization projects. The ability to produce stunning graphics on both light and dark materials opens up new creative avenues for brands looking to differentiate themselves in a competitive market. By exploring the benefits of DTF printing technology, businesses can better cater to consumer demands while reducing waste in the garment production cycle.

Direct-to-Film (DTF) transfer technology is quickly emerging as a game-changer in the realm of personalized clothing production. This innovative approach to fabric printing allows for intricate designs to be applied seamlessly onto a variety of textiles, catering to an increasing demand for unique apparel options. As new developments in sustainable printing solutions become available, the efficiency and adaptability of DTF processes are drawing attention from brands seeking to enhance their market presence. This shift not only promotes enhanced apparel customization but also aligns with the values of environmentally conscious consumers. In this exploration of DTF, we will delve into the transformative impact of this method on the apparel printing landscape.

Understanding the DTF Printing Process

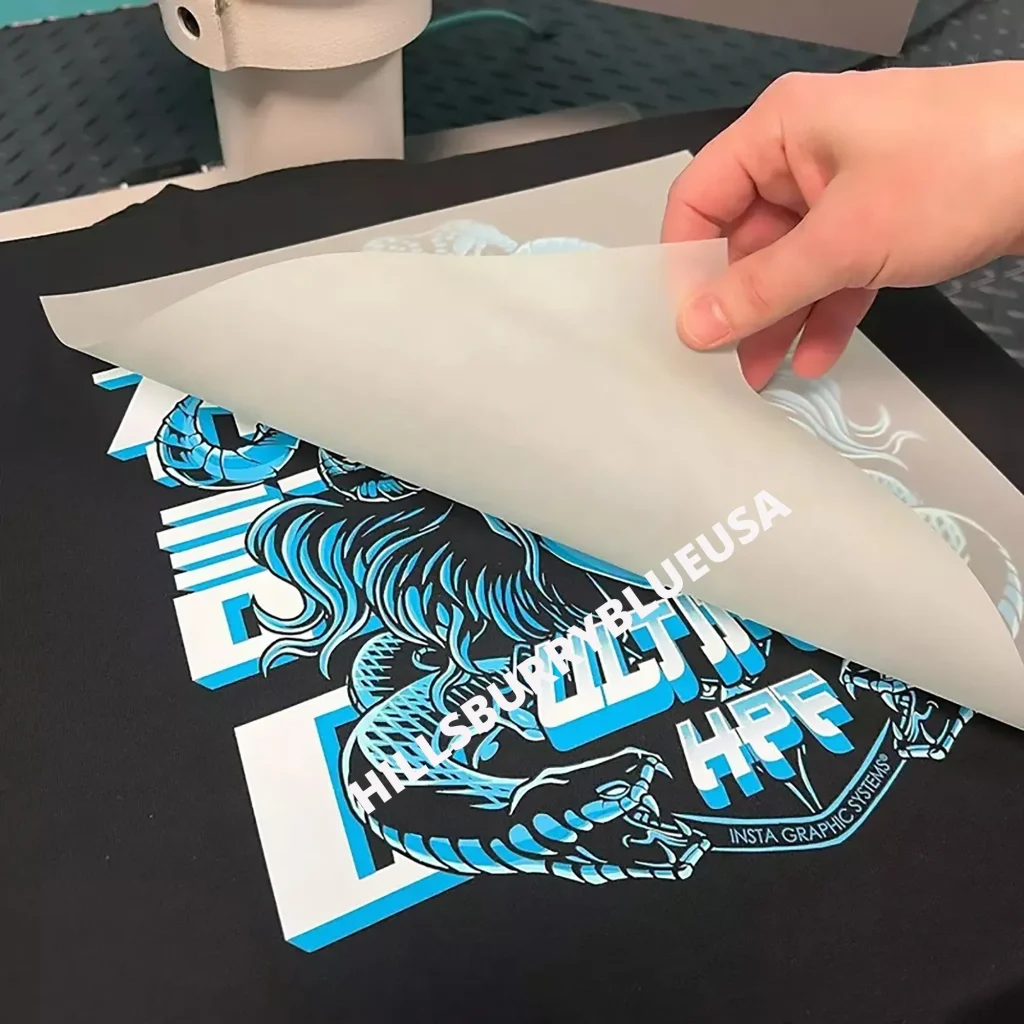

DTF printing technology revolutionizes the traditional methods of apparel decoration by introducing an innovative process that combines the simplicity of film printing with high-quality output. At its core, DTF (Direct-to-Film) transfers involve printing designs onto a special PET film that is then heat pressed onto the fabric. This technique distinguishes itself from Direct-to-Garment (DTG) printing by eliminating the need for pre-treating fabrics and enabling versatile applications across various textiles, including cotton, polyester, and blends. As brands embrace this technology, they benefit from the ease of use and minimal setup required, paving the way for more dynamic customization options.

Moreover, the flexibility of DTF printing extends to its compatibility with diverse fabric colors and textures, making it a preferred choice for many apparel businesses. Unlike other printing methods that may render subpar results on darker fabrics, DTF ensures crisp and vibrant transfers regardless of the textile’s hue. This ability not only satisfies customer demands for unique apparel but also opens opportunities for designers to create innovative styles without restrictions.

The Economic Benefits of DTF Transfers

One of the primary advantages of DTF transfers lies in their cost efficiency, particularly for small to medium-sized businesses. The lower initial investment compared to traditional screen printing setups allows new entrepreneurs to enter the custom apparel market without substantial financial risk. DTF technology streamlines the production process, enabling businesses to produce smaller quantities at an economical rate, which is especially beneficial for fulfilling custom orders without compromising profitability.

This cost-effective nature of DTF printing is further amplified by its quick production turnaround. With faster print speeds and the ability to handle multiple color designs without extensive setup changes, companies can respond to market demands more swiftly. This adaptability not only enhances customer satisfaction but also ensures that brands can capture emerging trends promptly, thus maintaining a competitive edge in the ever-evolving apparel industry.

Enhancing Print Quality with DTF Technology

The quality produced by DTF transfers is one of the standout features that attracts industry players to this printing technology. DTF printing is renowned for delivering vibrant colors and exceptional detail, rivaling even the most advanced printing methods available today. The advancements in ink formulation and transfer techniques allow for a durability that withstands multiple washes while retaining the integrity of the design—making it ideal for promotional items, sportswear, and everyday apparel alike.

Furthermore, the versatility of DTF technology contributes to its reputation for high-quality outputs on various fabric types. Unlike conventional methods that may struggle with intricate designs on textured materials, DTF ensures that every graphic element is faithfully reproduced, enhancing the overall appeal of the finished product. This capability not only meets consumer expectations but also cultivates brand loyalty as customers return for reliable quality in their custom apparel.

Sustainable Practices with DTF Printing

As sustainability takes center stage in the fashion industry, DTF printing is carving a niche as an eco-friendly alternative to traditional printing methods. Numerous manufacturers are embracing environmentally responsible practices by developing biodegradable inks and minimizing waste associated with fabric pre-treatment. This shift towards sustainable printing solutions resonates with eco-conscious consumers, allowing brands to position themselves favorably in a competitive market that values environmental responsibility.

Additionally, DTF technology’s efficiency reduces energy consumption and material waste, which is paramount in today’s eco-aware marketplace. By adopting DTF transfers, businesses can not only cater to the growing demand for personalized apparel but also align themselves with eco-friendly initiatives—making it a win-win for both the planet and profits. As brands continue to innovate within sustainable frameworks, the positive reputation garnered through DTF printing can ultimately lead to increased consumer loyalty and market growth.

The Role of Customization in DTF Printing

Customization has become a significant trend among consumers seeking unique apparel that reflects their personal style. DTF printing plays a vital role in facilitating this demand by enabling easy customization of designs without the need for extensive setup or equipment changes. From tailored team jerseys to personalized merchandise, DTF technology allows businesses to produce one-off designs alongside bulk orders, effectively broadening their market appeal.

As consumer preferences shift towards personalized products, businesses utilizing DTF printing can capitalize on this growing trend. Offering customers the ability to select colors, images, and fabric types through DTF transfers not only engages them but also drives sales. Customization through DTF not only satisfies individual tastes but also helps brands remain competitive by presenting unique options that set them apart from mass-produced apparel.

Future Trends in DTF Transfers and Apparel Customization

The future of DTF transfers is set to evolve with ongoing advancements in printing technology and consumer demand for personalized products. As more businesses recognize the benefits of this innovative printing method, we will likely see an increase in automated processes that enhance efficiency and output quality. Automation in DTF printing could lead to a significant reduction in human error and production timeline, allowing businesses to scale operations seamlessly.

Moreover, the development of superior ink technologies will further push the boundaries of what is possible in DTF transfers. Manufacturers are investing in creating inks that offer improved brightness, longevity, and eco-friendliness, thus catering to the needs of both businesses and conscious consumers. Alongside these advancements, the increasing emphasis on customization will fuel the growth of DTF printing, making it an essential component of the apparel industry’s future.

Frequently Asked Questions

What are DTF Transfers in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film and then transferring them onto fabric using heat and pressure. This technology allows for vibrant, high-quality prints on various materials, making it an ideal solution for custom apparel printing.

How does DTF printing technology differ from DTG printing?

Unlike Direct-to-Garment (DTG) printing, which is limited to specific fabric types, DTF printing technology offers versatility by allowing transfers on both light and dark fabrics. This capability makes DTF a preferred choice for businesses looking to create diverse custom designs.

What are the economic benefits of using DTF printing for apparel customization?

DTF printing is economically viable for small to medium-sized businesses due to lower initial costs compared to traditional screen printing. It enables cost-effective production of smaller print runs, helping brands meet custom order demands without incurring heavy financial losses.

Are DTF transfers an eco-friendly option for custom apparel printing?

Yes, DTF transfers are considered eco-friendly as many manufacturers are developing sustainable inks and processes. This reduces waste compared to traditional printing methods, aligning with the growing consumer demand for sustainable printing solutions in the fashion industry.

What challenges do businesses face when using DTF transfers?

Businesses adopting DTF transfers may encounter challenges such as market competition from established printing methods and maintaining consistent print quality. Overcoming these challenges often requires investing in reliable equipment and proper employee training.

What future trends can we expect in DTF printing technology?

The future of DTF printing technology includes the integration of automated processes for increased efficiency, advancements in ink technology for better quality prints, and a growing focus on sustainability. Additionally, the personalization trend in consumer preferences will boost demand for DTF printing in custom apparel.

| Key Points | Description |

|---|---|

| Advantages | DTF transfers offer versatility, cost-effectiveness, and high-quality prints on multiple fabric types. |

| Versatility | Can print on light and dark fabrics, making it ideal for a variety of designs. |

| Economic Viability | Lower setup costs compared to traditional methods, suitable for small to medium businesses. |

| High-Quality Prints | Produces vibrant, durable prints with excellent detail and color saturation. |

| Faster Production Speeds | New technology allows quicker order fulfillment, enhancing customer satisfaction. |

| Eco-Friendly Options | Innovative processes reduce waste and incorporate sustainable practices. |

| Challenges | DTF transfers face competition and quality control issues in the market. |

| Market Competition | Growing presence of DTF leads to increased emphasis on differentiating features. |

| Quality Control | New users must ensure consistent quality through reliable equipment and training. |

| Future Trends | The integration of automation and advancements in ink technology are anticipated. |

| Customization Trends | DTF caters to rising demand for personalized products. |

| Sustainability Initiatives | Practices aligning with sustainability are gaining traction in DTF printing. |

Summary

DTF Transfers represent the evolution of custom apparel printing by combining affordability and versatility, paving the way for businesses to tap into personalized consumer demands. This innovative method not only supports a wide variety of fabric types but also offers enhanced print quality and faster production times. As the printing landscape shifts, integrating DTF transfers will be crucial for entrepreneurs striving to remain competitive and sustainable in this rapidly changing industry.