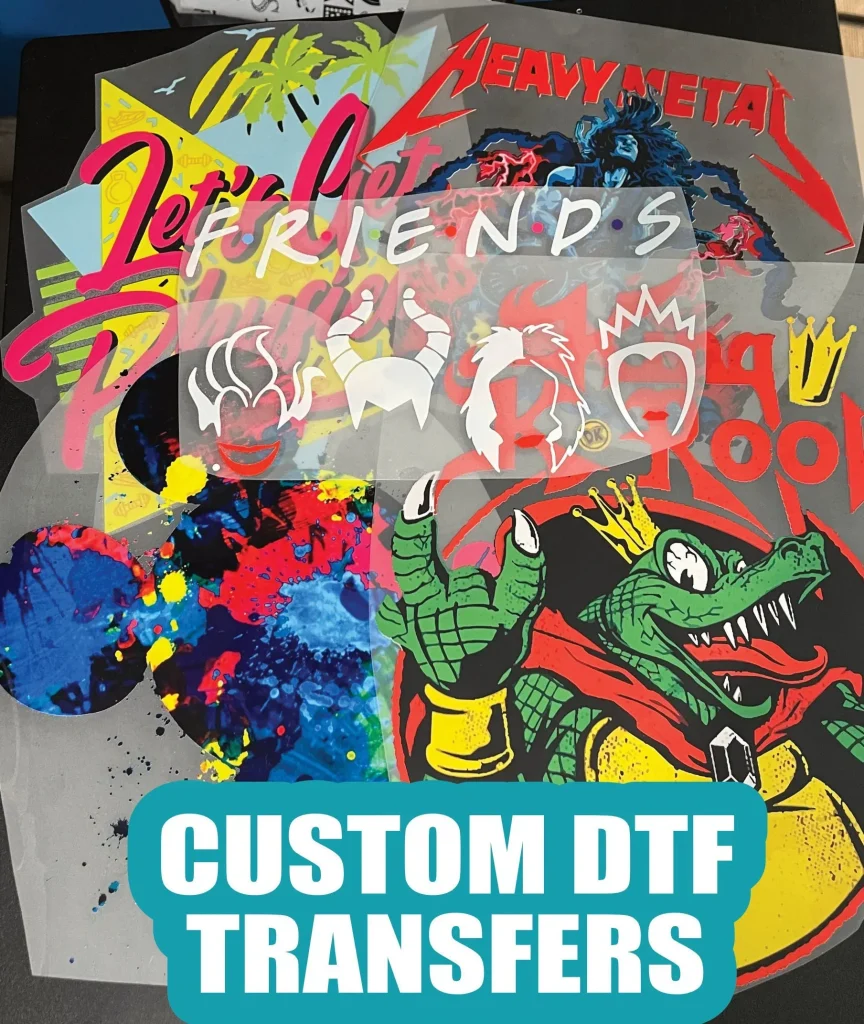

DTF transfers, or Direct to Film transfers, are rapidly reshaping the landscape of the garment industry, introducing a new era of fabric printing technology that prioritizes quality and efficiency. This innovative method allows intricate designs to be printed directly onto a film before being transferred onto various fabrics, ensuring vibrant colors and detailed graphics. As custom apparel becomes increasingly popular among consumers, the demand for versatile and effective printing solutions has surged, positioning DTF technology at the forefront of this transformation. This blog post will delve into the functionalities of DTF transfers, highlighting their advantages and the impact they are making in garment production today. With its remarkable potential, DTF transfers are not just a trend; they are an essential component of modern apparel manufacturing.

Direct to Film transfers offer a contemporary solution for printed fabric applications, rapidly gaining popularity in custom garment design. Through advanced digital printing techniques, these transfers facilitate high-quality images that can be easily applied to diverse fabrics. This process aligns perfectly with the growing trend of personalized clothing as it meets the demands of both small businesses and large-scale apparel manufacturers. Additionally, the versatility of this printing technology ensures it can adapt to various styles and materials, making it an ideal choice for innovative fashion. As we explore the intricacies of these transfers, we’ll uncover why this method is considered essential for the future of bespoke garment production.

Understanding DTF Transfers and Their Process

DTF transfers, or Direct to Film transfers, represent a remarkable shift in the way apparel is printed. This method involves printing designs onto a specially coated film which can then be heat-pressed onto the fabric. The process is more efficient compared to traditional methods, facilitating a faster turnaround and allowing for high-quality prints that are vibrant and detailed. The ability to print numerous colors in a single pass drastically reduces complexities in design execution, especially for intricate graphics that are prevalent in custom apparel.

The technology incorporates advanced fabric printing techniques that ensure the inks adhere firmly to a variety of materials including cotton, polyester, and blended fabrics. This flexibility not only enhances the range of products a business can offer but also ensures that the designs maintain their quality and integrity after numerous washes. Ultimately, DTF transfers provide a streamlined approach that caters to the growing demand for personalized fashion, making them a critical component in modern garment production.

The Benefits of Implementing DTF Transfers

One of the standout advantages of DTF transfers is their superior print quality. Unlike traditional printing methods that can struggle to accurately reproduce minute details, DTF technology excels at capturing the essence of complex designs, ensuring that every color and texture is represented with fidelity. This high level of detail is essential for brands looking to make a lasting impression with their custom apparel offerings, helping them stand out in a crowded marketplace.

Moreover, DTF transfers offer significant cost benefits, particularly for businesses focused on customization and small production runs. With the ability to print designs that include multiple colors without the need for extensive setup or materials, businesses can cut costs associated with screen printing. This not only makes DTF transfers more financially viable for smaller custom apparel shops but also encourages larger manufacturers to adopt this innovative technology to meet fluctuating market demands.

DTF Technology: A Game Changer for Custom Apparel

In the realm of custom apparel, DTF technology is proving to be a game changer. The rapid growth in consumer demand for unique and personalized clothing has pressured brands to adopt more efficient and versatile printing methods. DTF transfers allow for quick turnaround times without sacrificing quality, enabling businesses to fulfill orders faster and keep up with evolving customer preferences. This agility in production is crucial in today’s retail landscape where trends can shift overnight.

Additionally, DTF transfers enable businesses to experiment with a variety of fabric types and applications. This means that brands can easily branch into new product offerings such as sportswear, casual apparel, and promotional items—all with the same printing technology. By harnessing the capabilities of DTF, companies can diversify their catalog while effectively managing operational costs, ultimately driving sales and customer satisfaction.

DTF Transfers and Their Role in Sustainable Practices

The garment industry is increasingly recognizing the importance of sustainability, and DTF transfers are playing a pivotal role in this transition. Compared to traditional printing processes that often create significant waste due to excess inks and materials, DTF technology minimizes waste by allowing smaller print runs. This capability is particularly beneficial for brands focusing on eco-friendly practices, as it reduces the environmental footprint associated with overproduction and waste disposal.

Furthermore, the advancements in DTF technology have led to the development of inks and films that are more environmentally friendly. Manufacturers are now able to source materials that not only perform well under various conditions but also meet sustainability standards. This shift not only resonates with eco-conscious consumers but also positions businesses as leaders in adopting greener solutions within the garment industry.

Exploring Innovations Influencing DTF Transfers

The rapid advancements in printing technology have had a significant impact on DTF transfers, with innovations continually improving the efficiency and performance of this method. For instance, developments in ink formulations have led to more vibrant colors and longer-lasting prints, ensuring that designs remain intact even after multiple washes. These improvements are crucial in busy garment markets where product longevity can influence customer decisions.

In addition, innovations in film technology have enhanced the way DTF transfers adhere to fabrics, providing stronger bonds and better durability, which are essential qualities for any apparel. As manufacturers continue to refine these materials, DTF transfers are set to further dominate the landscape, offering unparalleled advantages that cater to both consumer preferences and industry standards.

The Future of DTF Technology in the Garment Industry

Looking ahead, DTF technology is poised to significantly shape the future of the garment industry. As the trend towards customization and personalization continues to grow, businesses that adopt DTF printing will find themselves at a competitive advantage. This printing method not only meets current market demands but also allows for innovative designs that are difficult to achieve with traditional techniques, giving brands the flexibility to adapt quickly to changing consumer tastes.

Moreover, as eco-friendly practices become a priority for both manufacturers and consumers, the sustainability aspects of DTF transfers will further elevate its status within the industry. The continued investment in research and development aimed at enhancing the efficiency and environmental impact of DTF technology suggests that it will remain a vital player in the future of garment printing. This direction not only supports businesses in meeting their operational goals but also aligns with broader efforts towards sustainable fashion.

Frequently Asked Questions

What are DTF transfers and how do they function in the garment industry?

Direct to Film (DTF) transfers are a cutting-edge printing technique that enables designs to be printed on a special film and then transferred onto fabric. This method simplifies traditional garment printing processes by allowing for high-resolution, multicolor designs to be created efficiently, making DTF ideal for the garment industry.

What are the key advantages of using DTF technology for custom apparel?

DTF technology offers numerous benefits for custom apparel, including superior print quality, versatility across different fabrics, cost-effectiveness by minimizing setup costs, and quick turnaround times for orders. These advantages support the growing demand for personalized clothing in the garment industry.

How do DTF transfers compare to Direct to Garment (DTG) printing?

While both DTF and Direct to Garment (DTG) printing produce high-quality images, DTF transfers excel in fabric adhesion, making them more durable on various materials. This characteristic makes DTF transfers preferable for a wider range of garments in the custom apparel market.

Can DTF transfers be used on any type of fabric?

Yes, DTF transfers are versatile and can be applied to a variety of fabrics, including cotton, polyester, and blends. This flexibility allows businesses in the garment industry to cater to different customer needs and expand their product offerings effectively.

What role does DTF technology play in the sustainability efforts of textile production?

DTF technology contributes to sustainability in textile production by reducing waste and allowing for smaller production runs without extensive setup. This minimizes environmental impact while still meeting the market’s demand for custom apparel and efficient production processes.

How has the market for DTF transfers evolved recently in the garment industry?

The market for DTF transfers has rapidly evolved as more businesses adopt this technology to meet consumer preferences for custom apparel. Increased educational resources, advancements in materials, and a focus on sustainability are key trends shaping the growth of DTF in the garment industry.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | A printing technique where designs are printed on a film and then transferred to fabrics, offering a streamlined process. |

| Key Advantages | 1. **Quality and Detail**: Produces high-resolution images with vibrant colors. 2. **Versatility**: Adheres to various fabrics. 3. **Cost-Effective**: Reduces costs associated with screen printing by allowing multicolor designs in one print. 4. **Quick Turnaround**: Faster production cycles for custom orders. |

| Industry Adoption | DTF transfers are increasingly adopted by both small custom businesses and large manufacturers due to consumer demand for personalized designs. |

| Trends and Developments (2023) | 1. Increased educational workshops about DTF printing. 2. Advancements in ink and transfer films for better durability. 3. A focus on sustainability in printing processes. |

| Comparison with Other Technologies | 1. **DTG Printing**: DTF offers better fabric permanence. 2. **Screen Printing**: DTF is more versatile for multicolor designs. |

Summary

DTF transfers are transforming the garment industry by providing innovative solutions for high-quality printing. This modern technology allows for quick and cost-effective production of customizable apparel, meeting the growing demand for unique designs. With its ability to adapt to various fabrics and simplify the printing process, DTF transfers have become a vital tool for businesses looking to enhance their offerings and stay competitive in a rapidly changing market. As companies increasingly focus on sustainability and efficiency, the role of DTF transfers is only expected to grow, making them essential for the future of garment manufacturing.