The DTF Gangsheet Builder is revolutionizing the landscape of Direct to Film printing by providing an innovative solution for creating efficient gang sheets. In a world where print optimization and cost-effectiveness are crucial, this advanced printing software stands out for its ability to enhance productivity while minimizing waste. Gone are the days of tedious manual layouts; with the DTF Gangsheet Builder, users can seamlessly arrange multiple designs onto a single sheet, making the printing process both faster and more economical. This tool not only promises high-quality outputs but also allows printers to harness the full potential of DTF printing technology. Whether for custom orders or bulk production, leveraging a DTF Gangsheet Builder is the key to streamlining your printing efforts and achieving exceptional results.

In the realm of digital textile printing, efficiency and innovation have taken center stage with cutting-edge software solutions like the DTF Gangsheet Creator. This state-of-the-art tool streamlines the process of gangsheet printing, enabling designers and print operators to optimize their workflows effectively. By allowing multiple graphics to be printed on a single film sheet, the gangsheet method enhances both speed and cost savings, addressing the demands of the modern printing market. Additionally, this advanced technology ensures that every print meets high-quality standards, aligning with the contemporary need for exceptional durability and vibrant colors. As we explore the intricacies of Direct to Film printing and its associated benefits, understanding tools like the DTF Gangsheet Creator becomes essential for businesses aiming for success in a competitive landscape.

Exploring the Advantages of DTF Printing Technology

DTF printing technology represents a significant leap from traditional printing methods, providing numerous advantages that modern businesses can capitalize on. One of the most notable benefits is the ability to print on a wide array of fabrics, including cotton, polyester, and blends. This adaptability means that fashion brands, custom merchandise suppliers, and promotional item manufacturers can produce vibrant and durable prints across multiple fabric types without needing extensive equipment modifications or additional materials.

Moreover, DTF printing simplifies the workflow for printers. The direct-to-film process allows creators to easily produce high-quality designs that can be transferred with consistent results. This eliminates common issues faced in screen printing or direct-to-garment (DTG) printing, such as color fading, peeling, or cracking, ultimately leading to higher customer satisfaction and repeat business.

Understanding Effective Gangsheet Printing

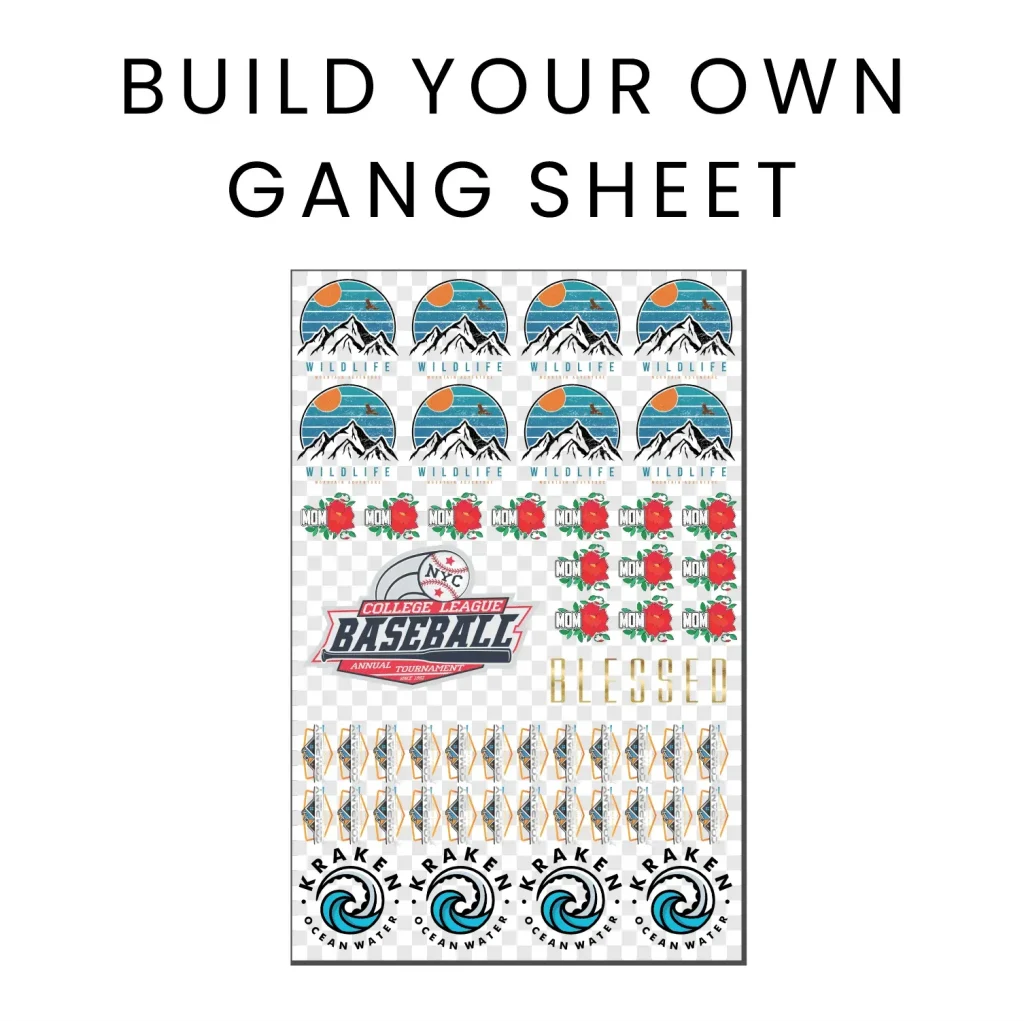

Gangsheet printing is a game-changer in optimizing production for print service providers. By allowing multiple designs to be printed on a single large sheet, it dramatically reduces setup times, material costs, and the overall footprint of printing operations. Instead of separately staging each design, printers can batch their output effectively, leading to significant gains in workflow efficiency.

Additionally, gangsheet printing reduces the amount of wasted material, which is often a critical concern for environmentally conscious businesses. By effectively utilizing the full sheet of film, printers not only lower their operating costs but also contribute to a more sustainable production model. This eco-friendly approach can enhance their brand image, particularly in markets where consumers value green practices.

The Essential Role of a DTF Gangsheet Builder

An advanced DTF Gangsheet Builder is central to harnessing the capabilities of DTF printing technology. This sophisticated software dramatically streamlines the design and production process by automating layouts that maximize the use of available space on the gang sheet. With tools that automatically adjust and fit various designs on a film, printers can focus more on creativity and less on manual labor.

Furthermore, having design editing tools integrated into the builder enables users to make on-the-fly adjustments efficiently, improving turnaround times on tight deadlines. Users can ensure that colors and placements are perfect before hitting print, resulting in a notable enhancement in the quality of the final product.

Achieving Print Optimization Through Software

Print optimization is critical in ensuring high-quality outputs while minimizing resource wastage. Advanced DTF printing software plays a pivotal role in achieving this by allowing printers to manipulate design parameters easily, ensuring that every print aligns with their artistic vision and meets customer specifications. Features like color management tools can help align the printer’s output with a business’s brand colors, ensuring consistency throughout the product line.

Moreover, the print optimization features enable printers to conduct batch trials to see how design tweaks impact output quality. By making data-driven decisions on printing setups, businesses can enhance their final products further, which can lead to higher-quality merchandise that elevates consumer experiences.

Cost-Efficient Production with DTF Gangsheet Builder

The reduction of costs through the use of an advanced DTF Gangsheet Builder can significantly benefit both small and large businesses. By enabling printers to combine multiple designs onto one sheet, it eliminates overspending on film materials and reduces the overall cost per unit. This efficiency can create a valuable competitive advantage in the bustling printing marketplace.

Additionally, for startups or smaller operations that might contend with budget limitations, utilizing a gangsheet builder minimizes the financial burdens of production. By lowering the costs associated with raw materials and labor, businesses can allocate resources toward growth initiatives or marketing, enhancing their market presence.

Sustainability in DTF Printing Processes

In an era where sustainability is increasingly becoming a deciding factor for buyers, the printing industry must adapt. DTF printing, particularly when utilizing a gangsheet builder, presents a unique opportunity to commit to eco-friendly practices. By maximizing film usage and minimizing waste, these advanced systems align printing operations with common sustainability goals.

Furthermore, businesses that adopt sustainable printing practices often experience enhanced brand loyalty. Consumers today favor brands that consider their environmental impact, and by showcasing these practices, print service providers can not only attract clientele but also enhance their corporate reputation as responsible, forward-thinking enterprises.

Frequently Asked Questions

What are the key features of a DTF Gangsheet Builder?

An advanced DTF Gangsheet Builder comes equipped with features such as automatic layouts, design editing tools, preview functionalities, and compatibility with various file formats, all aimed to streamline the gangsheet printing process.

How does DTF printing technology enhance the printing process?

DTF printing technology allows for high-quality output that is efficient and versatile, enabling printers to transfer designs onto multiple fabric types while reducing waste and maximizing productivity through the use of a DTF gangsheet builder.

What benefits does gangsheet printing offer for small orders?

Gangsheet printing optimizes production by printing multiple designs on a single sheet, significantly reducing material waste and costs, which is particularly beneficial for businesses handling smaller or custom orders.

Can an advanced DTF Gangsheet Builder improve print quality?

Yes, an advanced DTF Gangsheet Builder enhances print quality by ensuring proper alignment and adjustments during the design process, leading to improved accuracy and consistently high-quality prints.

Why is print optimization important in DTF printing?

Print optimization in DTF printing is crucial as it maximizes the use of film and reduces waste, thereby lowering production costs and enhancing operational efficiency, which is facilitated by using an advanced DTF gangsheet builder.

How can I ensure my designs are ready for DTF printing?

To prepare designs for DTF printing, make sure they are high-resolution and properly color calibrated. Utilizing the design editing tools in a DTF Gangsheet Builder can also help optimize your artwork for the best printing results.

| Key Point | Description |

|---|---|

| DTF Printing | Revolutionizes textile printing with high-quality, fast outputs using heat and pressure. |

| Gangsheet Definition | Large sheets where multiple designs are printed together, reducing waste and costs. |

| Advanced DTF Gangsheet Builder | Software that optimizes design layouts, editing, and previews, enhancing efficiency. |

| Benefits | 1. Increased efficiency in printing. 2. Cost-effective by minimizing material waste. 3. Improved quality control for consistent prints. 4. Versatile applications for various designs. 5. Sustainable practice reducing environmental impact. |

| Tips for Usage | 1. Keep learning to maximize software capabilities. 2. Test materials before large batches. 3. Optimize designs for best output. 4. Engage with the DTF community for support. |

Summary

DTF Gangsheet Builder is set to transform your printing experience by offering enhanced efficiency and quality. This innovative tool allows print businesses to streamline their workflows, enabling faster production times and reducing costs through optimized material use. By adopting an advanced DTF gangsheet builder, you can achieve stunning, durable prints while also contributing to a more sustainable printing process. It’s a powerful solution for businesses looking to stay competitive in the printing industry.