The DTF Gangsheet Builder serves as a game-changing tool for those immersed in the world of Direct-to-Film (DTF) printing. By leveraging this innovative technology, custom garment designers and print shops can enhance their workflow efficiency and produce multiple transfers on a single sheet of film. This not only saves valuable resources but also ensures a consistent quality across all prints when the right gang sheet layout is applied. In this article, we will delve into effective DTF tips and explore the intricacies of using transfer film to create stunning designs that stand out. Get ready to master the heat press technique for flawless results with every transfer you create!

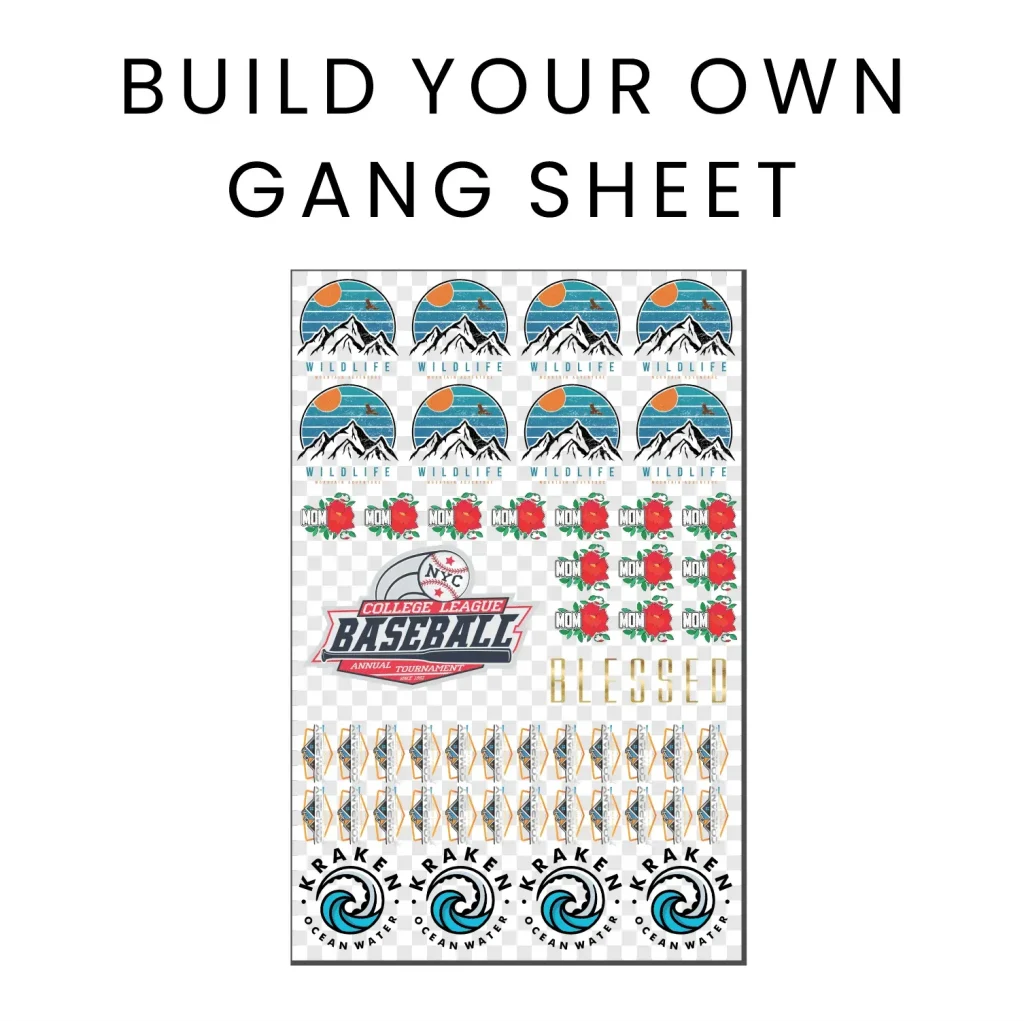

Introducing the DTF Gangsheet Builder, a revolutionary software designed to optimize the Direct-to-Film printing process. This powerful tool not only simplifies the arrangement of graphics on your transfer sheets but also maximizes production efficiency by allowing multiple designs to be printed simultaneously. With a focus on the precise layout known as a gang sheet, users can enjoy reduced material waste and improved print quality. Whether you’re a small business or a large print shop, understanding the nuances of DTF printing techniques will empower you to deliver exceptional products that meet client demands. As we embark on this exploration of transfer film and the art of creation, prepare to uncover essential tips that will elevate your printing game.

Understanding DTF Printing Techniques

DTF printing, or Direct-to-Film printing, has gained popularity among textile designers for its ability to create vibrant and durable prints. This technique involves printing designs onto a specialized film using high-quality DTF inks before they’re transferred onto garments. Understanding the intricacies of DTF printing is essential as it not only affects the final product’s appearance but also its longevity and color accuracy. Utilizing the right tools, including a DTF gangsheet builder, can help streamline this process and ensure that every transfer is of the highest quality.

Moreover, the refinement in techniques surrounding DTF printing, such as optimizing the gang sheet layout, can drastically enhance the workflow. Knowing how to adjust printer settings, maintain your equipment, and select the best transfer films can lead to superior results. Each step from design to execution must be meticulously planned to achieve the stunning results that DTF printing promises.

Maximizing Efficiency with Gang Sheet Layouts

Using a DTF gangsheet builder allows you to create layouts that maximize efficiency by fitting multiple designs onto a single sheet of film. This setup not only conserves materials but also saves time, particularly for bulk orders. Thoughtful arrangements of designs can minimize waste, streamline the cutting process, and improve production times. Organizing designs that share similar colors or themes helps in achieving uniformity and quality across multiple prints.

Additionally, a well-designed gang sheet layout can enhance your ability to manage production schedules effectively. By grouping similar artwork and allowing adequate space for weeding, you minimize the risk of overlapping. Proper use of software to preview layouts before printing can also ensure that everything aligns correctly, thus reducing the chances of errors during the printing process. This strategic approach not only improves efficiency but also leads to higher profitability.

Color Management for Accurate Transfers

In DTF printing, effective color management is critical for reproducing designs accurately on garments. Utilizing the right color profiles for your printer and transfer film is essential for maintaining color fidelity from the design stage to the final print. One of the key DTF tips is to conduct test prints before finalizing larger runs. This practice allows you to make necessary adjustments to ensure that the colors match your expectations and the original design.

Moreover, understanding how different fabrics and materials interact with various inks can further refine color output. Experimenting with prints on sample fabrics and adjusting the settings accordingly can help achieve the best possible results. By taking these color management strategies seriously, you can elevate the quality of your DTF prints and ensure that your customers receive products that meet their expectations.

Choosing the Right Transfer Film

When it comes to DTF printing, the transfer film you choose plays a significant role in the quality of the final product. High-quality films specifically designed for DTF printing ensure that colors remain vibrant and adhere properly during the transfer process. By selecting the best transfer film that matches your DTF inks, you will significantly enhance the durability and visual impact of your prints.

Additionally, the surface texture of the transfer film can affect the end result. A smooth texture is often preferred for achieving high-quality prints, as it allows for better ink adhesion and overall print clarity. It’s crucial to experiment with different types of films to find the best fit for your projects, as quality and compatibility will ultimately impact the success of your DTF printing endeavors.

Mastering Heat Press Techniques

The heat press technique is an integral part of the DTF printing process, and mastering it can drastically enhance the quality of your transfers. Consistent temperature and pressure are crucial to ensure that the adhesive bonds effectively with the fabric. This requires an understanding of both the material being printed on and the specific requirements of the transfer film, as different combinations may demand unique heat settings.

Experimenting with timing can also yield significant advantages. Some materials require longer heat exposure to achieve a solid bond, while others may be sensitive to excessive heat. Keeping a detailed record of each setting used for different fabrics will create a valuable resource for future projects and help in maintaining consistency across production runs.

Post-Transfer Care for Long-Lasting Prints

To ensure the longevity of DTF prints, proper post-transfer care is vital. Educating your customers on how to wash and maintain their printed garments can greatly extend the life of the transfers. For instance, advising them to turn garments inside out before washing can help protect the print, while using cold water and avoiding harsh detergents can preserve colors.

Furthermore, allowing the garment to cool completely after the transfer enhances the adhesive bond, ensuring that the print remains intact during wear. This care is essential not only for customer satisfaction but also for building a reputation for quality in your custom garment business, as high-quality prints will keep clients returning for more.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it work?

A DTF Gangsheet Builder is a tool used in Direct-to-Film (DTF) printing to create multiple design transfers on one sheet of transfer film. It maximizes efficiency by allowing users to batch print designs, reducing material waste and production costs while ensuring consistent quality across all transfers.

What are the benefits of using a DTF Gangsheet Builder in DTF printing?

Using a DTF Gangsheet Builder enhances efficiency by combining multiple designs, minimizes wasted transfer film, and ensures uniform quality through consistent ink application and curing processes across prints.

How do I optimize my gang sheet layout for better results?

To optimize your gang sheet layout, arrange designs thoughtfully by grouping similar items, leaving enough space to avoid overlaps, and using design software to preview layouts, ensuring all designs fit within the dimensions of the transfer film.

What are some DTF tips for selecting the right transfer film?

When selecting transfer film for DTF printing, choose high-quality films compatible with your ink, consider the surface texture for better print adhesion, and always perform test prints to ensure durability and vibrancy.

What heat press techniques should I follow when using a DTF Gangsheet Builder?

For effective heat pressing in DTF printing, maintain consistent temperature and pressure, experiment with timing for different materials, and keep a log of successful settings for future reference, ensuring successful transfer adhesion.

How can I maintain quality after using a DTF Gangsheet Builder on printed garments?

To maintain the quality of printed garments, allow them to cool completely post-transfer to strengthen bond adhesion and educate customers on proper washing and drying instructions to prolong the lifespan of their DTF prints.

| Tip/Aspect | Details |

|---|---|

| Understanding DTF Printing | Combination of digital design, printing on film, applying adhesive, and transferring to garments. |

| Benefits of DTF Gangsheet Builder | Maximized efficiency, reduced costs, consistent quality. |

| Proper Design Setup | Set artwork at 300 DPI, prefer vector formats (AI, SVG). |

| Color Management | Use correct color profiles, conduct test prints for color accuracy. |

| Selecting Transfer Film | Choose high-quality film and consider film texture. |

| Optimizing Gang Sheet Layout | Group similar designs, ensure proper spacing, preview layout. |

| Printer Settings and Maintenance | Adjust settings per the manual, maintain printer regularly. |

| Heat Press Techniques | Control temperature, pressure, and experiment with timings. |

| Post-Transfer Care | Allow cooling, educate customers on washing instructions. |

Summary

The DTF Gangsheet Builder is an indispensable tool for achieving perfect transfers in the DTF printing process. By understanding the printing technique, leveraging the benefits of gang sheets, and implementing key tips such as proper design setup and color management, you elevate your printing quality and efficiency. Embrace these strategies and watch your custom garment creations achieve new heights, ensuring customer satisfaction and business success.